Our Services

Table of Contents

Diesel Engine Service and Maintenance

At NASS Engineering Services Pvt Ltd, we have an outstanding team of qualified, and trained engineers and technicians handling engine overhauls, troubleshooting, and managing repair jobs onboard the vessel, oil rig, and at the docks.

NASS Engineering Services Pvt Ltd’s Services for Diesel Engines

– Top and Major Overhauling

– Troubleshooting and Repair

– Inspection and Trouble shooting

Rolls-Royce / Bergen

NASS Engineering Services Pvt Ltd has dedicated service team for Bergen KRMB-8, KRMB-9, KVMB-12, KVMB-16, B32:36, B32:40, C25:33 Engine overhauls, maintenance and Trouble shooting

Caterpillar

3516B, 3512, 3412, 3408, 3406, 3306, D399, D398, C32, C18, C11, C9

Detroit

4-71, 6-71, 8V71, 12V71, 8V92, 16V92 and 60 Series Detroit Engines

EMD (Electro-Motive Diesel)

645 & 710 Series

MaK

8M20C, 8M25C, 8CM32, 8M43C

Cummins

6BTA, QSK50, KT19, QSM, NTA855

Yanmar

6N165, 6EY18, 6EY22, 6EY26, 6EY33

Niigata

MG17HX, MG19HX, MG22HX, MG25HX, MG26HLX, MG28HX, MG28HLX, MG28AHX, MG31HX

Other Engines

Daihatsu, MTU, Wartsila, MAN, Kirloskar, Yamaha Outboard engines, Perkins, Leyland, Volvo Penta, Lister Petter, Waichai, etc.

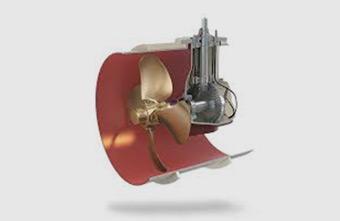

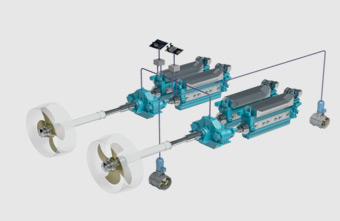

Azimuth and Thrusters Overhaul

We at NASS Engineering Services Pvt Ltd has trained and specialized team – Bow / Thunnel Thruster and & Azimuth overhaul in dry dock.

We also undertake overhaul of Niigata Z Peller (ZP31, ZP41), Kawasaki thrusters, Schottle.

Crankshaft Grinding

We here at NASS Engineering Services Pvt Ltd are experts at grinding diesel engine crankshafts. Crankshaft grinding consists of removing a minute amount of finished material from the rod and main journals to rebuild the part back to OEM spec. The full crankshaft remanufacturing process is quite intensive but is critical to complete engine rebuild.

Engine Block Line Boring

Line boring is a very important task, but it is also one that takes the right equipment and the right talent. In many situations, these are simple applications, but in others, they can be very complex requiring a special level of skill. This is especially true in situations where custom solutions are necessary. And at NASS Engineering Services Pvt Ltd will provide you with the right equipment and the right talent required for carrying out the engine block line boring.

Turbocharger Overhaul

At NASS Engineering Services Pvt Ltd, we have a qualified and experienced team handling turbochargers overhaul including rotor balancing and bearings renewal for ABB make.

Governor Overhaul

We do carry out the complete overhauls for the governors of Woodward and Zexel make.

In Situ Liner Honing

Periodical honing can minimize operational cost and increase the service life of cylinder liners and piston rings. For reducing blow by and scuffing as well as lube oil consumption, it is highly recommended to honing the running surface of liner regularly. And we at NASS Engineering Services Pvt Ltd provide you with the provision of in situ liner honing with special tools.

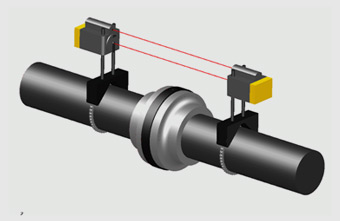

Laser alignment and Vibration analysis

Condition monitoring is the process of monitoring a parameter of condition in machinery (vibration, temperature etc.), in order to identify a significant change which is indicative of a developing fault. It is a major component of predictive maintenance. The use of condition monitoring allows maintenance to be scheduled, or other actions to be taken to prevent consequential damages and avoid its consequences. Condition monitoring has a unique benefit in that conditions that would shorten normal lifespan can be addressed before they develop into a major failure. Condition monitoring techniques are normally used on rotating equipment, auxiliary systems and other machinery (compressors, pumps, electric motors, internal combustion engines, presses).

We here at NASS Engineering Services Pvt Ltd provide with two condition monitoring techniques i.e. Laser Alignment and Vibration Analysis.

CP (Controllable Pitch) and FP (Fixed Pitch) PropellersOverhaul

We have dedicated team with special tools for Schottel and Berg Propulsion controllable pitch and fixed pitch propeller work which includes seal renewal, stern tube reconditioning and propeller blades reconditioning.

Waterjets Overhaul

We have team for Waterjets overhaul, Routine maintenance.

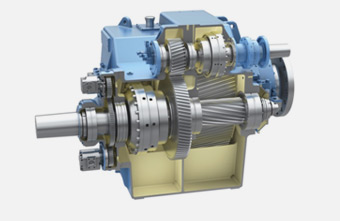

Marine Gear Box:

We have specialize team for ZF Gear box and stocking spare parts

Dye Penetrant (DP) Test and Magnetic Particle Inspection (MPI)

Magnetic particle inspection is often carried out to help determine an item’s fitness for use or conformity. The method can detect surface or near-surface flaws such as cracks, laps, seams and inclusions in ferromagnetic materials such as iron and steel. One of the main advantages of magnetic particle inspection is that it can give an immediate indication of defects and discontinuities.

We at NASS Engineering Service Pvt Ltd offers best service in Dye Penetrant (DP) Test and Magnetic Particle Inspection (MPI) for various engine components, propeller shafts and blades, etc.

Complete vessel refit and dry dock

We at NASS Engineering Service Pvt Ltd specialize in complete vessel refit and dry dock services, ensuring top-notch maintenance and restoration for hulls, propulsion systems, and critical maritime structures.

Dry Docking:

Our dry dock facilities are equipped to handle vessels of various sizes and types. Services include:

• Hull inspection & cleaning

• Blasting, painting & anti-fouling

• Shaft, rudder, propeller maintenance

• Underwater hull repairs & steel renewal

• Class surveys and third-party inspections

Vessel Refit & Overhaul

From minor retrofits to complete system replacements, we offer comprehensive refit services:

• Engine and generator overhaul

• Electrical & automation system upgrades

• HVAC, plumbing & fire suppression retrofits

• Navigation, communication & bridge equipment updates

• Interior refurbishment (cabins, galleys, mess halls)

Mechanical & Structural Repairs

• Steel and aluminium structural repairs

• Pipe fabrication & replacement

• Tank inspections & recoating

• Deck machinery servicing

Testing & Compliance

• Non-destructive testing (NDT)

• Load testing & trials

• Class society coordination

• Regulatory documentation & reporting

Our Capabilities

• Dry Dock facility

• Round-the-Clock Operations: 24/7 crew and flexible scheduling

• Certified Workforce

• Quality Assurance: ISO-certified processes, safety-first culture

We are committed to delivering cost-effective, high-quality solutions that restore vessels to peak condition—ensuring long-term performance and compliance.