Thrusters play a critical role in the safety, maneuverability, and operational stability of offshore vessels. From dynamic positioning to precise navigation in harsh marine environments. thrusters ensure that vessels perform at peak efficiency despite rough seas, strong currents, and demanding offshore operations.

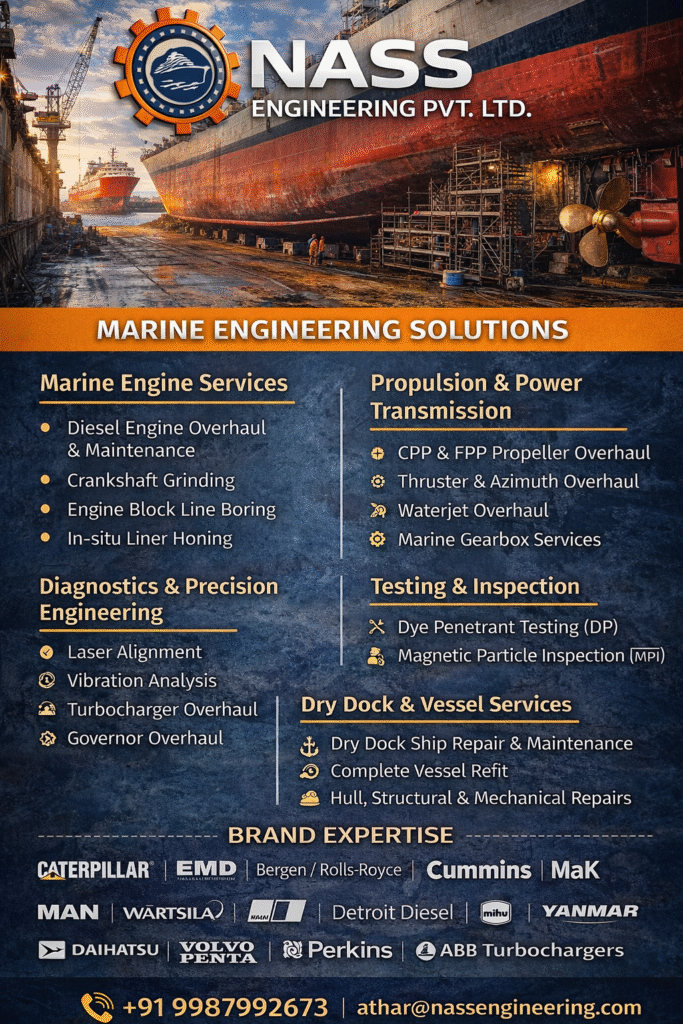

At NASS Engineering Services Pvt. Ltd., we specialize in complete Bow Thruster and Azimuth Thruster overhaul, using OEM-approved procedures and genuine spare parts to guarantee long-term reliability.

What Are Thrusters and Why Are They So Important?

Thrusters are auxiliary propulsion systems that provide side thrust and maneuvering capability. Offshore vessels rely heavily on them for docking, station keeping, positioning, and precision movement.

A well-maintained thruster ensures:

- Safe vessel maneuverability

- Reduced fuel consumption

- Improved dynamic positioning performance

- Lower vibration and noise

- Extended equipment life

Without regular maintenance. even a minor fault can lead to major failures and expensive downtime.

Common Types of Thrusters Used in Offshore Vessels

At NASS Engineering. we work with all major thruster types and models used globally:

Bow Thrusters

Used for lateral movement during docking and maneuvering.

Azimuth Thrusters (Z-Drive / L-Drive)

Provide 360-degree rotational propulsion. crucial for offshore DP (Dynamic Positioning) vessels.

Tunnel Thrusters

Mounted within the hull. offering powerful side thrust for tight navigation.

Niigata Z-Peller, Kawasaki, Schottel & Rolls-Royce/Ulstein Thrusters

These are widely used in OSVs. tugs. navy vessels and offshore rigs.

We handle complete overhaul for all major OEM brands.

Why Thruster Overhaul Is Essential

Thrusters face extreme stress due to:

- Continuous rotation under high loads

- Corrosion from seawater

- Seal failures

- Gear wear

- Hydraulic system fatigue

Neglecting timely overhaul causes:

- Reduced maneuverability

- Overheating of gear mechanisms

- Water ingress into the gear housing

- Excessive vibration

- Complete thruster breakdown

This leads to delays. mission failure. and heavy repair costs for offshore assets.

When Should You Schedule a Thruster Overhaul?

Industry, class and OEM guidelines recommend overhaul after:

- 8,000–15,000 running hours

- During dry-docking cycles

- When vibration, leakage, or noise is detected

- After long-term operation in corrosive or sandy environments

If your vessel shows any signs of performance drop. it’s time to schedule an inspection.

Our Thruster Overhaul Expertise

NASS Engineering Services Pvt. Ltd. offers complete thruster solutions for offshore and marine vessels. including:

- Bow Thruster Overhaul

- Azimuth Thruster Overhaul

- Niigata Z-Peller Overhaul

- Schottel Thruster Overhaul

- Kawasaki Thruster Overhaul

- Rolls-Royce / Ulstein Thruster Overhaul

Our team handles both dockyard and onboard operations depending on your requirements.

Step-by-Step: How We Overhaul Your Thruster

1. Initial Condition Assessment

We inspect mechanical. hydraulic. electrical. and sealing components to detect anomalies.

2. Dismantling

The thruster is safely removed and dismantled using OEM-approved tools.

3. Component Cleaning & Inspection

All parts are cleaned chemically and visually inspected for wear.

4. Gear & Bearing Inspection

We check tooth patterns, backlash, and bearing condition with precision instruments.

5. Seal Replacement

We replace worn-out seals with OEM-approved or genuine seals to prevent water ingress.

6. Shaft Inspection & Alignment

We check run-out, straightness and perform laser alignment during assembly.

7. Reassembly

The thruster is assembled with controlled torque settings as per manufacturer guidelines.

8. Testing & Commissioning

We perform functional testing and load simulations before handing over.

Why Choose NASS Engineering for Thruster Overhaul

Expert Team with Global Capability

Our engineers are trained to handle major thruster systems. and hold CDC certificates to attend vessels worldwide.

OEM-Approved Procedures

We follow strict guidelines from Niigata, Schottel, Rolls-Royce, Kawasaki, and Ulstein.

Genuine Spare Parts

We supply and install authentic components to maintain long-term reliability.

ISO-Certified Quality Standards

Certified under ISO 9001:2015, ensuring consistent quality and documentation.

Complete Propulsion Support

From CPP / FPP propellers, gearboxes, waterjets, and engines. NASS handles full propulsion system service.

👉 Services Page:

Explore All Propulsion & Marine Services

Signs Your Thruster Needs Immediate Attention

- Oil leakage around seals

- Unusual noise or vibration

- Reduced thrust performance

- Overheating

- Water contamination in gear oil

- Trouble maintaining DP position

Early detection prevents major breakdowns.

Industries We Serve

- Offshore Supply Vessels

- Oil & Gas Platforms

- Tugs & Workboats

- Defence & Coast Guard Vessels

- Research & Survey Ships

- Power Plant Cooling Water Systems

Value-Added Services We Provide

- Oil Analysis & Condition Monitoring

- Laser Alignment

- Vibration & Noise Analysis

- Dye Penetrant Testing (DP)

- Magnetic Particle Inspection (MPI)

- Propulsion System Audit Reports

Why Offshore Vessel Owners Trust NASS Engineering

With clients like Indian Navy, Indian Coast Guard, Cochin Shipyard, Goa Shipyard, and major offshore operators, we have proven capability in delivering thruster solutions that meet stringent performance and compliance requirements.

Contact Us for Thruster Overhaul & Repair

If your vessel requires thruster inspection, overhaul, or spare parts support, our team is ready to assist.

📍 Navi Mumbai | Visakhapatnam | Kolkata | UAE | Saudi Arabia

📞 +91 9987992673

✉️ service@nassengineering.com

🌐 nassengineering.com