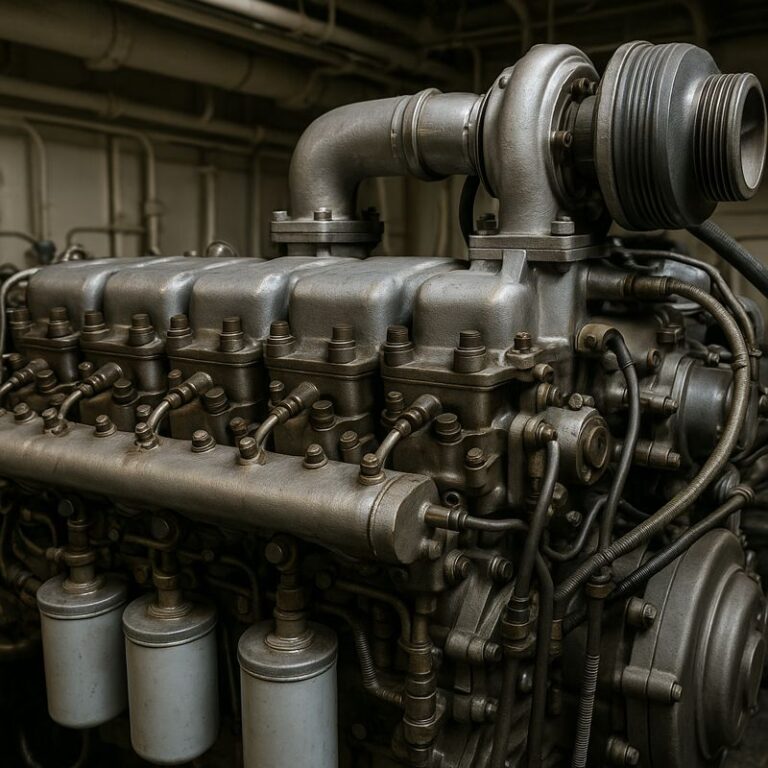

Marine diesel engines are engineered for reliability, heavy loads, and long operational cycles.

Yet, even the most robust engines face failures when exposed to harsh marine environments, fluctuating loads, improper maintenance, and fuel quality issues.

Understanding why diesel engines fail is the first step toward preventing downtime, costly repairs, and safety risks.

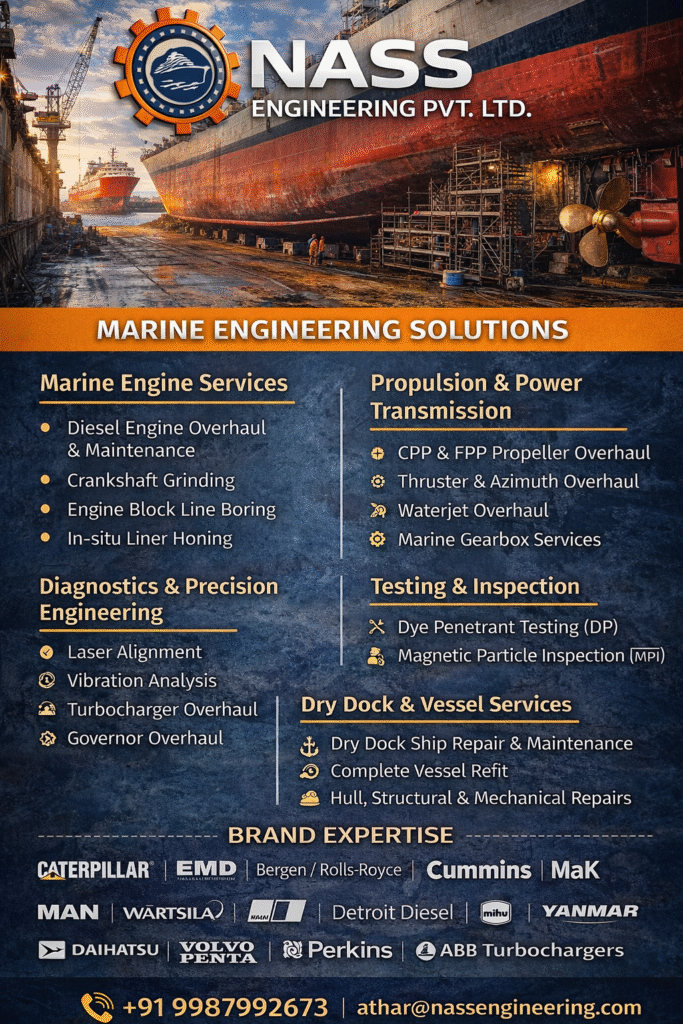

As marine engineering specialists, NASS Engineering Services Pvt. Ltd. brings deep technical insight into the root causes of engine failures and how proper diagnostics and maintenance can prevent them.

Why Marine Diesel Engines Fail — A Research-Based Perspective

Marine engines work under extreme conditions: high temperature, constant vibration, corrosion, continuous load changes, and contaminated operating environments.

Most failures are predictable — if the underlying science is understood.

Below are the most common scientific and engineering causes of marine diesel engine failures.

1. Fuel Injection System Problems

The fuel system is the heart of combustion. When it fails, the entire engine suffers.

Why It Happens

- Wear in injectors

- Clogged nozzles

- Incorrect spray pattern

- Low fuel pressure

- Contaminated fuel (water, sludge, sulphur deposits)

Impact

- Poor combustion

- Excessive smoke

- High fuel consumption

- Misfiring and knocking

- Premature piston/ring wear

Fuel injectors and pumps must follow OEM specifications for spray angle, atomization, and injection timing.

2. Lubrication Failure

One of the leading causes of catastrophic engine damage.

Why It Happens

- Low oil pressure

- Oil contamination

- Wrong lubricant grade

- Blocked filters

- Overextended oil change intervals

Impact

- Bearing seizure

- Piston scuffing

- Turbocharger damage

- High wear rate in liners and rings

Proper lubrication reduces friction and removes heat — when lubrication fails, engines fail.

3. Overheating & Cooling System Issues

Marine engines rely heavily on efficient heat removal.

Why It Happens

- Blocked seawater strainers

- Scale in heat exchangers

- Cooling pump failure

- Low coolant levels

- Thermostat malfunction

Impact

- Thermal stress

- Cracked cylinder heads

- Loss of power

- Oil degradation leading to bearing failure

Heat is the primary enemy of engine life.

4. Combustion Chamber Deposits

Improper combustion forms carbon deposits on:

- Cylinder heads

- Valves

- Piston crowns

- Turbocharger turbines

Why It Happens

- Poor fuel quality

- Inaccurate injection timing

- Low operating loads (wet stacking)

Impact

- Reduced power

- High exhaust temperatures

- Turbocharger fouling

- Inefficient combustion

5. Air Intake & Turbocharger Problems

Marine environments increase the risk of air filter clogging and turbocharger fouling.

Common Issues

- Dirty filters

- Bearing wear

- Rotor imbalance

- Corrosion

- Incorrect boost pressure

Impact

- Loss of power

- Poor acceleration

- High fuel consumption

- Risk of catastrophic turbine failure

Turbocharger health is directly linked to engine efficiency.

6. Mechanical Wear & Fatigue

Over time, critical components wear due to:

- Continuous stress cycles

- Metal fatigue

- Poor lubrication

- Corrosion

- Misalignment

Vulnerable parts include:

- Crankshaft

- Connecting rods

- Bearings

- Camshafts

- Liners and pistons

If not caught early, these failures become expensive.

7. Poor Quality or Incorrect Spare Parts

This is an often-ignored but major cause of failure.

Impact of Non-OEM Parts

- Incorrect material composition

- Poor tolerances

- Early wear

- Seal failures

- Loss of compression

Marine engines require high-precision components — using incorrect parts drastically reduces reliability.

8. Installation & Alignment Errors

Improper alignment causes:

- High vibration

- Bearing overload

- Premature shaft wear

- Seal leakage

- Gearbox stress

Laser alignment and vibration analysis are crucial for long-term performance.

9. Corrosion & Saltwater Exposure

Saltwater accelerates corrosion in:

- Cylinder liners

- Cooling jackets

- Exhaust manifolds

- Fuel lines

- Engine blocks

Corrosion weakens metal, creates leaks, and increases operating temperature.

10. Operator Error & Inadequate Maintenance

Human factors account for nearly 40% of marine engine failures (industry studies).

Common mistakes:

- Running engines at low loads

- Ignoring alarms

- Delayed oil and filter changes

- Incorrect warm-up/cool-down routines

- Poor record keeping

Proper training and monitoring greatly reduce failure rates.

How to Prevent Marine Diesel Engine Failure — Expert Recommendations

Based on years of engineering and research, here are the most effective preventive measures:

1. Follow OEM Overhaul Intervals

Top overhaul • Major overhaul • Running hours checklist

2. Implement Predictive Maintenance

Use:

- Vibration analysis

- Oil analysis

- Exhaust temperature monitoring

- Bearing condition monitoring

Predictive methods detect failures before they occur.

3. Maintain Fuel & Lubrication Quality

- Use certified fuel

- Replace filters regularly

- Use correct oil grade

- Avoid mixing different lubricant types

4. Keep Cooling Systems Clean

- Flush heat exchangers

- Clean seawater strainers

- Maintain coolant concentration

5. Ensure Proper Alignment

Laser alignment reduces wear and vibration drastically.

6. Use Genuine Spare Parts

OEM-tested components ensure proper tolerances and long-term reliability.

7. Train Crew & Enforce SOPs

Human error prevention saves significant downtime.

Why NASS Engineering Is a Trusted Name in Engine Overhaul & Diagnostics

NASS provides:

- Diesel engine overhauls for CAT, Bergen, EMD, Detroit, Cummins, MAN, Daihatsu, Wartsila

- Predictive diagnostics (vibration, alignment, NDT, oil analysis)

- Turbocharger overhaul

- Fuel pump & injector calibration

- Onboard troubleshooting

- Genuine spare parts supply

- ISO-certified quality processes

With a technically skilled and globally deployable engineering team, we ensure your engines operate at peak performance.

Conclusion — Understanding Failure Science Improves Reliability

Marine diesel engine failures rarely happen without warning.

By understanding the science behind engine wear, combustion quality, lubrication, and component fatigue, operators can take proactive steps to avoid breakdowns and extend engine life.

With expert servicing, diagnostics, and overhaul support, NASS Engineering Services Pvt. Ltd. helps vessels operate safely, efficiently, and reliably across global waters.