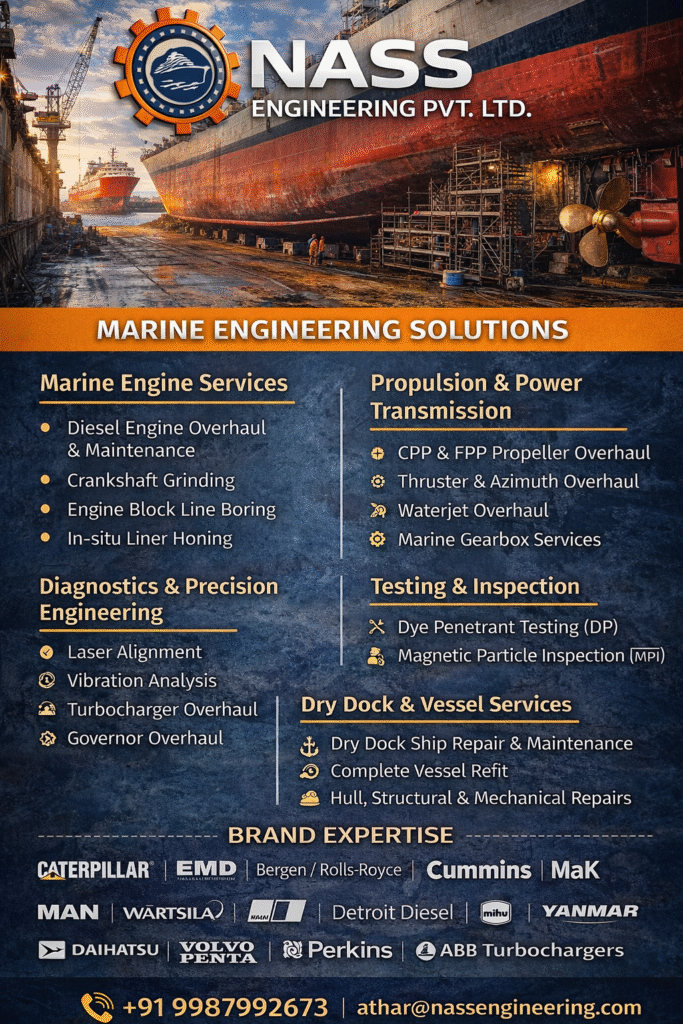

Marine diesel engines are the beating heart of every vessel. Whether it’s a cargo ship, offshore platform, or coast guard vessel — reliable engine performance determines everything from fuel efficiency to safety. Over time, however, even the most powerful engines require professional overhaul and maintenance to continue delivering optimal output.

At NASS Engineering Services Pvt. Ltd., we specialize in marine diesel engine overhauling, repairs, troubleshooting, and diagnostics — ensuring your vessel stays sea-ready, always.

Why Engine Overhaul Matters

Marine engines operate under extreme conditions: high loads, saltwater corrosion, and continuous running hours. Without scheduled overhauls, minor wear can lead to major breakdowns and costly downtime.

A complete engine overhaul:

- Restores engine performance and fuel efficiency

- Reduces emissions and lube oil consumption

- Extends engine lifespan

- Prevents unplanned maintenance and downtime

Regular servicing not only protects your investment but also ensures compliance with IMO (International Maritime Organization) and classification society standards.

When Should You Overhaul Your Marine Engine?

It depends on running hours, manufacturer recommendations, and operational conditions.

However, some common indicators include:

- Noticeable drop in power output or efficiency

- Unusual vibration or noise

- Excessive smoke or fuel consumption

- Low compression or oil contamination

Following OEM guidelines for periodic Top and Major Overhauls helps prevent sudden failures and keeps your operations consistent.

Our Engine Overhaul Expertise

At NASS Engineering, our highly trained engineers and technicians handle both in-situ and workshop-based overhauls for leading marine engine brands, including:

- Rolls-Royce Bergen (KRMB, KVMB, B32:40, C25:33 Series)

- Caterpillar (CAT) – 3516B, 3512, 3412, C32, and more

- Detroit (GM) – 4-71, 8V71, 16V71, 60 Series

- EMD (Electro-Motive Diesel) – 645 & 710 Series

- MaK, Cummins, Wartsila, MAN, Daihatsu, MTU and others

Every overhaul project is executed following strict OEM standards, safety protocols, and ISO 9001:2015 quality processes.

Step-by-Step: Our Overhaul Process

1. Initial Inspection & Diagnosis

We begin with detailed engine condition assessment — visual checks, compression tests, and vibration analysis — to identify wear patterns and performance issues.

2. Component Dismantling

Critical components like cylinder heads, pistons, crankshafts, and liners are carefully dismantled, tagged, and inspected.

3. Cleaning & Measurement

We clean and measure components using precision tools to detect cracks, scoring, or out-of-tolerance parts.

4. Repair & Reconditioning

Defective parts are either repaired or replaced with genuine OEM or reconditioned components. NASS maintains stock for CAT, Bergen, MAN, Detroit, and other brands.

5. Assembly & Alignment

Reassembly follows strict torque and clearance specifications. Laser alignment ensures perfect shaft and gear fit.

6. Testing & Calibration

We perform full functional tests — including fuel injection, cooling, and lubrication systems — before the final run.

7. Sea Trials & Documentation

Each overhaul is documented with test reports, measurements, and photographs. We also provide Class survey coordination when required.

Why Choose NASS Engineering for Your Engine Overhaul

Authorized Distributorships

We are authorized distributors for top global brands:

- Bosch Fuel Injection Systems

- MANN+HUMMEL Centrifugal Oil Filters

- ENI Lubricants (Marine & Offshore Range)

This ensures genuine spare parts, warranty-backed products, and OEM-standard servicing.

Skilled Technical Team

Our engineers hold CDC (Continuous Discharge Certificates), enabling them to perform engine overhauls on vessels during sailing — anywhere in the world.

ISO-Certified Quality

NASS Engineering is ISO 9001:2015 certified by the Indian Register of Quality Systems (IRQS), ensuring process-driven excellence across all operations.

End-to-End Capability

From crankshaft grinding, line boring, and turbocharger overhaul to propulsion system repair, we handle complete marine powertrain solutions under one roof.

Common Challenges We Solve

- Frequent engine breakdowns or overheating

- Low fuel efficiency and irregular combustion

- Unbalanced crankshaft or misaligned shaft

- Contaminated lube oil or coolant leaks

- Exhaust smoke or turbocharger failure

By addressing the root cause — not just the symptom — we ensure lasting performance and reliability.

Value-Added Services

In addition to overhauling, we provide:

- Vibration analysis & laser alignment

- Governor and turbocharger overhaul

- Dye Penetrant & Magnetic Particle Inspection (MPI)

- Condition monitoring and predictive maintenance

- Fuel pump and injector calibration (Bosch-certified)

Keeping Fleets Moving Since 2016

From defence vessels to offshore platforms and cargo ships, NASS Engineering has supported major organizations including:

Indian Navy, Indian Coast Guard, Cochin Shipyard Ltd, Goa Shipyard Ltd, and Shipping Corporation of India.

Our dedication to reliability, safety, and timely delivery makes us the preferred engineering partner for marine operators worldwide.

Contact Us for Marine Engine Overhaul Support

Need a professional engine overhaul or maintenance inspection?

Reach out to our expert service team today.

📍 Head Office: Navi Mumbai, India

📞 Call: +91 9987992673

✉️ Email: service@nassengineering.com