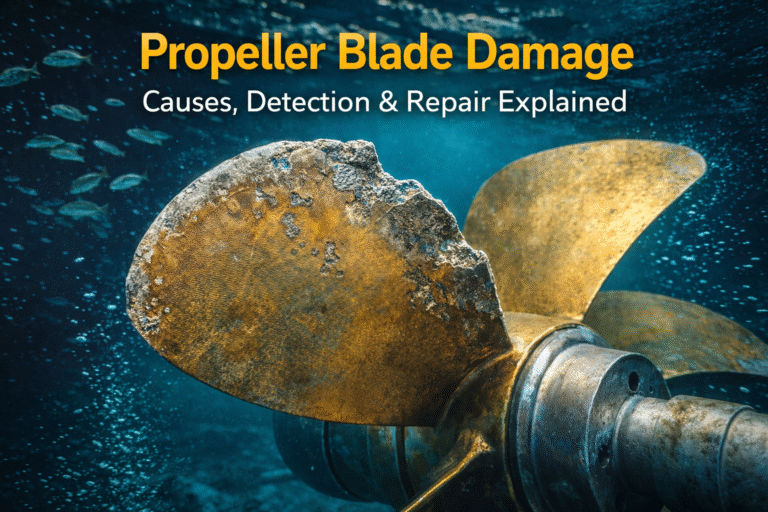

Propeller blades are among the most highly stressed components of any marine propulsion system. They operate continuously under heavy load, variable speeds, corrosive seawater, and unpredictable underwater conditions.

Even minor blade damage can significantly reduce vessel efficiency, increase fuel consumption, generate vibration, and accelerate wear in shafts, bearings, and gearboxes.

From a marine engineering and research perspective, understanding why propeller blades fail, how damage develops, and when repair is required is critical for safe and efficient vessel operation.

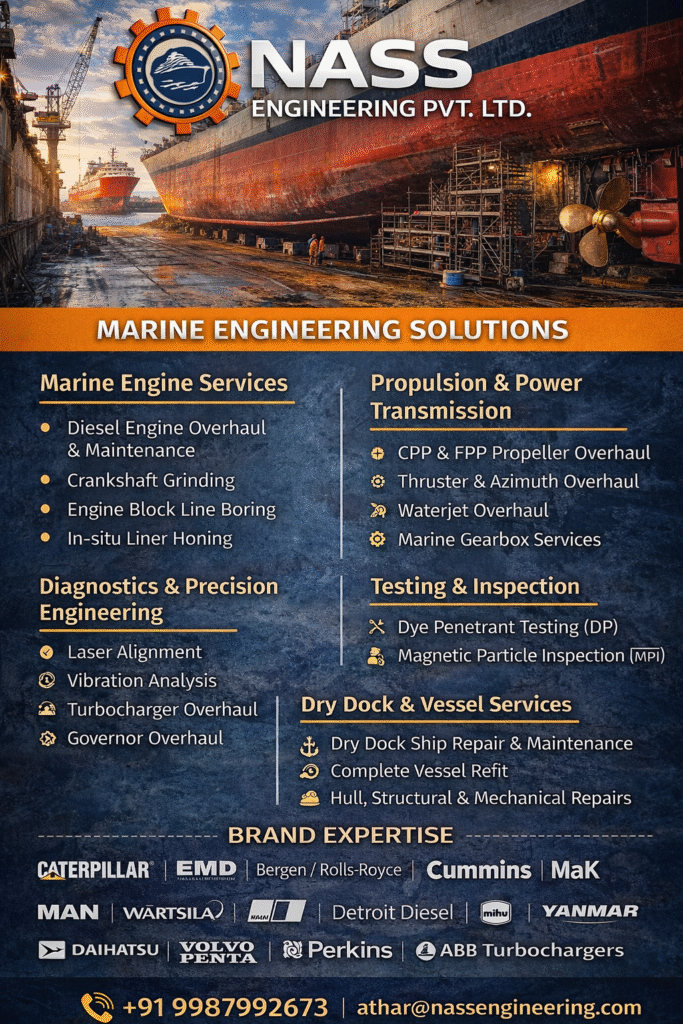

At NASS Engineering Services Pvt. Ltd., propeller inspection, reconditioning, and repair form a key part of our propulsion system services during dry docking and operational maintenance.

Why Propeller Blade Condition Is So Critical

A propeller converts engine power into thrust. Any deviation in blade shape, balance, or surface condition directly affects propulsion efficiency.

Damaged propellers can cause:

- Loss of thrust

- Increased fuel consumption

- High vibration levels

- Shaft misalignment

- Bearing and seal failure

- Gearbox overload

- Structural fatigue

In severe cases, propeller damage can compromise vessel safety.

Common Types of Propeller Blade Damage

Marine research and field experience show that propeller damage typically falls into the following categories.

1. Cavitation Damage

Cavitation occurs when pressure drops around the blade surface cause vapor bubbles to form and collapse violently.

Causes

- High rotational speed

- Incorrect blade pitch

- Poor blade profile

- Improper clearance between blade and hull

Effects

- Pitting on blade surfaces

- Loss of material

- Reduced thrust efficiency

- Increased vibration and noise

Cavitation damage often appears first near the blade trailing edge.

2. Impact Damage

Propellers frequently strike:

- Floating debris

- Logs

- Containers

- Rocks or seabed

- Ice (in certain regions)

Effects

- Bent blades

- Chipped edges

- Cracks

- Sudden imbalance

Impact damage must be addressed immediately to prevent further structural failure.

3. Corrosion & Erosion

Seawater is highly corrosive, especially in polluted or high-salinity regions.

Causes

- Electrochemical corrosion

- Improper cathodic protection

- Galvanic interaction with hull materials

Effects

- Blade thinning

- Surface roughness

- Reduced efficiency

- Increased cavitation risk

Corrosion accelerates fatigue and crack formation.

4. Fatigue Cracking

Repeated cyclic loading leads to metal fatigue over time.

Common Locations

- Blade root

- Hub connection

- High-stress zones near pitch change areas (CPP systems)

Fatigue cracks can propagate silently and lead to blade failure if not detected early.

5. Improper Pitch or Blade Deformation

Incorrect blade pitch or deformation causes uneven load distribution.

Consequences

- Engine overload

- Increased fuel consumption

- Poor maneuverability

- Vibration throughout propulsion train

This is particularly critical in CPP (Controllable Pitch Propeller) systems.

How Propeller Damage Is Detected

1. Visual Inspection

During dry docking, blades are checked for:

- Cracks

- Edge damage

- Surface pitting

- Deformation

However, visual inspection alone is not enough.

2. Vibration Analysis

Damaged blades cause:

- Imbalance

- Fluctuating thrust

- Cyclic vibration

Vibration monitoring often detects propeller issues before visible signs appear.

3. Non-Destructive Testing (NDT)

Common NDT methods include:

- Dye Penetrant (DP) testing

- Magnetic Particle Inspection (MPI)

These detect surface and near-surface cracks invisible to the naked eye.

4. Pitch & Geometry Measurement

Blade pitch and geometry are measured to confirm compliance with OEM specifications.

Effects of Ignoring Propeller Damage

Failing to repair propeller damage leads to:

- Rapid bearing wear

- Shaft misalignment

- Seal failure

- Gearbox damage

- Increased dry dock frequency

- Higher lifecycle costs

Marine studies show that damaged propellers can increase fuel consumption by 5–15%.

Propeller Repair Techniques Used in Marine Engineering

1. Blade Straightening

Bent blades are carefully reshaped using controlled mechanical and thermal methods.

2. Surface Reconditioning

Grinding and polishing restore blade profile and smoothness, reducing cavitation risk.

3. Crack Repair

Cracks are repaired using certified welding techniques followed by stress relief and inspection.

4. Pitch Adjustment

For CPP systems, blade pitch is recalibrated to ensure uniform thrust distribution.

5. Dynamic Balancing

Balancing ensures smooth rotation and eliminates vibration caused by mass imbalance.

When Should a Propeller Be Repaired or Replaced?

Repair Is Suitable When

- Damage is localized

- Blade thickness remains within limits

- Cracks are repairable

- OEM tolerances can be restored

Replacement Is Required When

- Structural integrity is compromised

- Severe corrosion is present

- Fatigue cracks extend deep into blade root

- OEM geometry cannot be restored

Professional evaluation determines the safest option.

CPP vs FPP — Propeller Damage Considerations

CPP Systems

- More complex

- Sensitive to pitch mechanism damage

- Require precise sealing and calibration

FPP Systems

- Simpler design

- More tolerant of minor damage

- Still require strict balance and profile accuracy

Both systems demand expert handling.

How NASS Engineering Handles Propeller Repair

NASS Engineering provides:

- CPP and FPP propeller inspection

- Blade repair and reconditioning

- Pitch calibration

- Seal replacement

- Dynamic balancing

- NDT testing

- Dry dock support and class coordination

Our marine engineers follow OEM-approved repair procedures and international quality standards.

Best Practices to Prevent Propeller Damage

Marine research and operational experience recommend:

- Regular underwater inspection

- Monitoring vibration trends

- Maintaining correct alignment

- Avoiding excessive RPM in shallow water

- Ensuring proper cathodic protection

- Prompt repair after minor damage

Prevention always costs less than repair.

Conclusion — Healthy Propellers Mean Efficient Vessels

Propeller blade condition directly impacts vessel efficiency, safety, and operating costs.

Understanding damage mechanisms and addressing issues early ensures reliable propulsion and long service life.

With specialized expertise in propulsion systems, NASS Engineering Services Pvt. Ltd. supports vessel owners with professional propeller inspection, repair, and overhaul services across marine, offshore, and defence sectors.