In marine engineering, precision is not optional. Even a small alignment error between an engine, gearbox, and propulsion shaft can lead to excessive vibration, premature bearing failure, seal damage, and significant fuel losses.

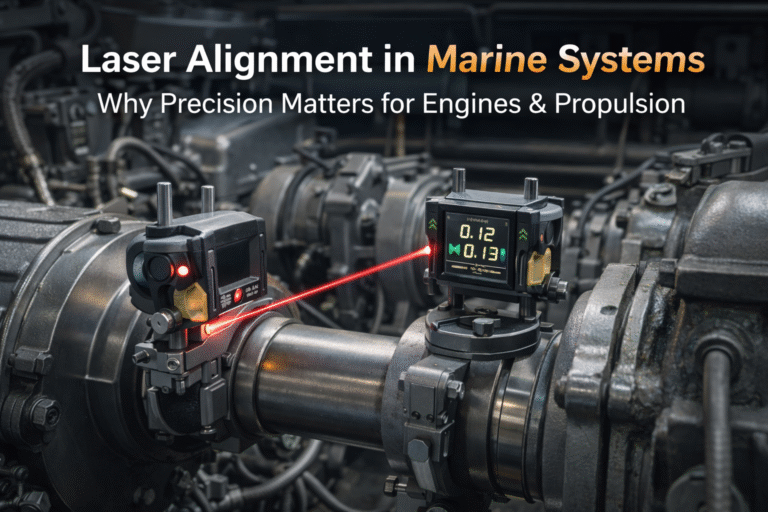

Laser alignment has become the industry standard for achieving the accuracy required in modern marine engines and propulsion systems. Unlike traditional dial methods, laser alignment delivers measurable, repeatable, and highly precise results.

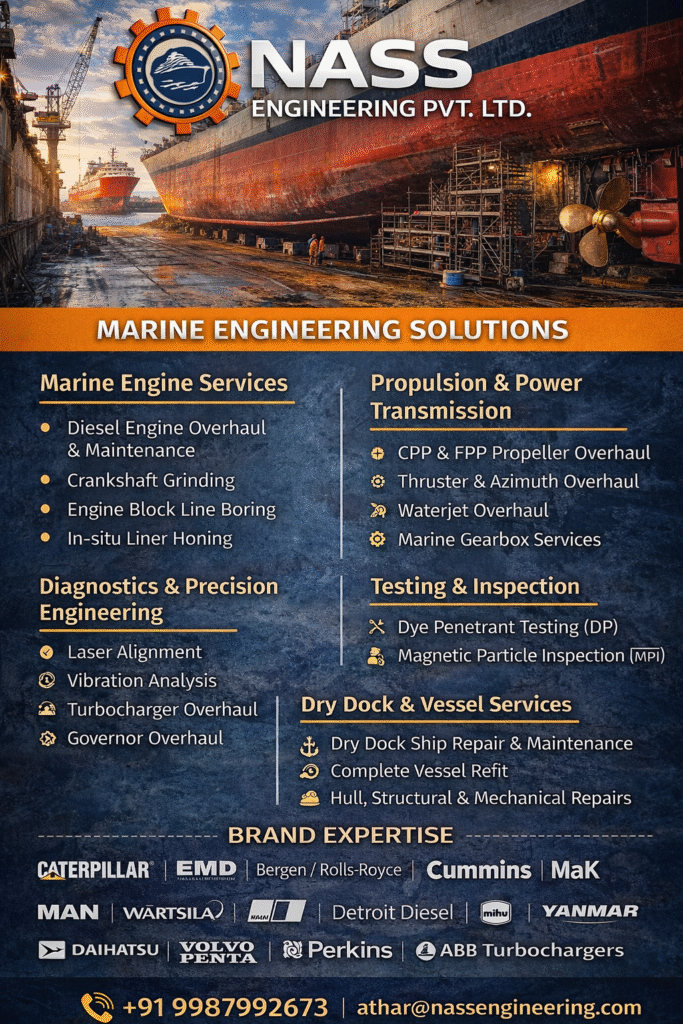

At NASS Engineering Services Pvt. Ltd., laser alignment is a core diagnostic and corrective service used across marine, offshore, power, and defence vessels.

What Is Laser Alignment in Marine Engineering?

Laser alignment is a precision measurement technique used to align rotating machinery so that their shafts operate on the same centerline under running conditions.

Using laser transmitters and sensors, engineers measure:

- Angular misalignment

- Parallel (offset) misalignment

- Vertical and horizontal deviation

Corrections are calculated digitally, allowing alignment to be achieved within microns.

Why Alignment Is Critical in Marine Systems

Marine machinery operates under:

- High torque

- Continuous loads

- Hull flexing

- Thermal expansion

- Dynamic sea conditions

Even minor misalignment can escalate rapidly.

Poor alignment leads to:

- High vibration levels

- Excessive bearing and seal wear

- Shaft fatigue

- Coupling damage

- Gearbox stress

- Increased fuel consumption

Correct alignment protects every downstream component.

Marine Equipment That Requires Laser Alignment

Laser alignment is essential for:

• Main Propulsion Engines

Ensures smooth power transfer from engine to gearbox.

• Gearboxes

Prevents uneven gear loading and tooth wear.

• Propulsion Shafts

Reduces shaft bending, bearing overload, and seal failure.

• Thrusters (Bow & Azimuth)

Maintains gear and bearing life under heavy maneuvering loads.

• Waterjet Drive Lines

Ensures pump efficiency and vibration control.

• Generator Sets

Improves reliability and reduces alternator bearing wear.

Types of Misalignment Found in Marine Vessels

1. Angular Misalignment

Shafts meet at an angle.

Effects:

- High axial vibration

- Seal leakage

- Rapid bearing wear

2. Parallel (Offset) Misalignment

Shafts are parallel but not collinear.

Effects:

- Increased radial load

- Coupling damage

- Elevated temperatures

3. Combined Misalignment

Most common in marine vessels.

Effects:

- Severe vibration

- Repeated component failure

- Reduced system life

Laser alignment detects all three accurately.

Why Traditional Alignment Methods Fall Short

Dial gauge alignment has been used for decades, but it has limitations:

| Factor | Dial Gauge | Laser Alignment |

|---|---|---|

| Accuracy | Moderate | Very high |

| Setup time | Long | Fast |

| Thermal compensation | ❌ No | ✅ Yes |

| Hull deformation allowance | ❌ No | ✅ Yes |

| Repeatability | Low | High |

| Documentation | Manual | Digital |

Modern marine systems demand laser precision.

How Laser Alignment Is Performed Onboard

1. Initial Condition Check

Engine mounts, foundations, couplings, and bolts are inspected.

2. Laser Setup

Laser transmitters and sensors are mounted on shafts or coupling hubs.

3. Measurement & Data Capture

Readings are taken at multiple shaft positions to calculate misalignment.

4. Thermal Growth Compensation

Marine engines expand when operating. Laser systems compensate for this factor.

5. Correction & Adjustment

Shims and position adjustments are applied as per calculated values.

6. Final Verification

Post-alignment measurements confirm accuracy and stability.

Benefits of Laser Alignment in Marine Operations

• Reduced Vibration

Proper alignment lowers vibration at the source.

• Extended Bearing & Seal Life

Correct load distribution prevents premature failures.

• Improved Fuel Efficiency

Reduced mechanical losses improve energy transfer.

• Lower Maintenance Costs

Fewer breakdowns and emergency repairs.

• Higher Equipment Availability

Reliable machinery means less downtime.

Laser Alignment vs Vibration Analysis — How They Work Together

- Vibration analysis identifies the problem

- Laser alignment corrects the root cause

Together, they form the foundation of predictive maintenance.

When Should Laser Alignment Be Performed?

Marine research and industry best practices recommend laser alignment:

- After engine or gearbox overhaul

- After dry docking

- After bearing or seal replacement

- When vibration levels increase

- When coupling wear is observed

- During commissioning of new equipment

Skipping alignment is one of the most common causes of repeat failures.

Common Alignment Mistakes Seen in Marine Vessels

- Aligning without considering thermal growth

- Ignoring soft foot conditions

- Using worn shims

- Not tightening bolts to final torque before measurement

- Skipping final verification

Experienced engineers prevent these errors.

How NASS Engineering Delivers Precision Alignment

NASS Engineering combines:

- Advanced laser alignment tools

- Experienced marine engineers

- Knowledge of hull behavior and thermal effects

- Integration with vibration analysis

- Alignment during sailing or at dock

Our alignment services support engines, gearboxes, thrusters, waterjets, and auxiliary machinery.

Real Impact for Vessel Owners

Proper laser alignment results in:

- Longer overhaul intervals

- Reduced spare parts consumption

- Improved operational reliability

- Lower lifecycle costs

- Safer vessel operation

For offshore and defence vessels, this precision is mission-critical.

Conclusion — Alignment Precision Protects Your Assets

Laser alignment is not just a maintenance task — it is a reliability strategy.

By ensuring precise shaft alignment, marine operators protect engines, propulsion systems, and gearboxes from avoidable damage.

With expert diagnostics and precision alignment services, NASS Engineering Services Pvt. Ltd. helps vessels operate efficiently, safely, and reliably across demanding marine environments.