Dry docking is one of the most critical phases in a vessel’s lifecycle. It’s the only time a ship is completely accessible for structural inspection, underwater repairs, hull treatment, propulsion maintenance, and class compliance checks.

From a marine engineering perspective, dry docking is not just routine maintenance — it is risk prevention, performance restoration, and operational cost control.

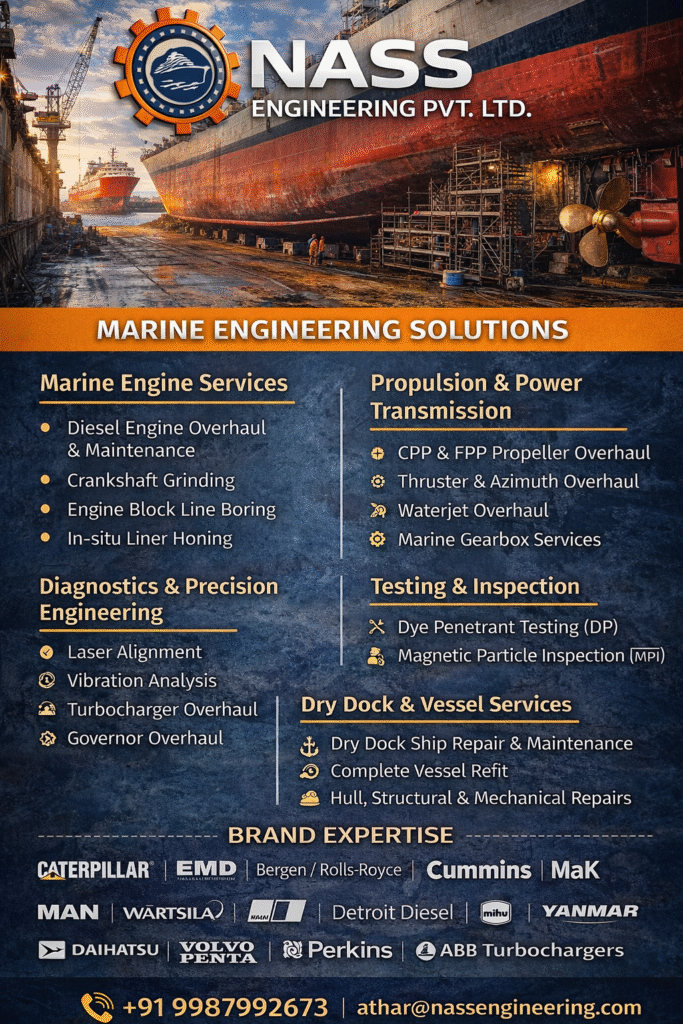

At NASS Engineering Services Pvt. Ltd., we bring years of practical experience in marine engineering, vessel refits, propulsion overhaul, and dry-dock project execution across offshore, defence, and commercial fleets.

What Is Dry Docking and Why Is It Essential?

Dry docking involves taking a vessel out of water using a dry dock, slipway, or floating dock, allowing marine engineers and surveyors to perform critical underwater inspections and repair work.

Dry docking is essential because it helps:

- Restore vessel performance

- Reduce fuel consumption by up to 20% through hull cleaning

- Prevent structural failures

- Comply with class and statutory requirements

- Detect corrosion before it spreads

- Extend the vessel’s operational life

Most international regulators and classification societies (IRS, DNV, ABS, LR, BV) mandate dry docking every 2–5 years, depending on vessel type.

How Dry Docking Works: Step-by-Step Breakdown

As marine engineering specialists, NASS follows globally accepted procedures to ensure safety and precision during dry docking.

1. Pre-Docking Inspection & Planning

Before the vessel enters dock, engineers examine:

- Hull condition

- Propulsion systems

- Steering gear

- Sea-water valves

- Cathodic protection status

- Previous repair records

A detailed docking plan is prepared covering equipment, manpower, timelines, and class survey requirements.

2. Docking the Vessel

Once aligned over the keel blocks, the water is pumped out gradually.

During lowering:

- Hull stability is monitored

- Stress points are checked

- Stern and propeller areas are observed carefully

This phase demands strict engineering oversight to avoid structural misalignment.

3. Hull Inspection & Cleaning

Marine fouling is a major cause of fuel inefficiency.

Key tasks include:

- High-pressure water blasting

- Fouling removal (barnacles, algae, marine growth)

- Structural crack inspection

- Thickness measurement of plates

A clean hull can improve fuel efficiency by 6–20%, depending on fouling severity.

4. Propulsion System Overhaul

This is the core area where NASS specializes.

During dry docking, propulsion systems such as propellers, CPP/FPP units, shafts, stern-tubes, and thrusters are completely accessible.

Typical tasks include:

- Removal & reconditioning of propeller blades

- CPP hub inspection and seal replacement

- Shaft alignment checks

- Bearing clearance measurement

- NDT testing (MPI/DP)

- Waterjet and thruster overhaul

- Gearbox inspection

Proper propulsion maintenance reduces vibration, improves fuel efficiency, and enhances maneuverability.

5. Hull Treatment & Coating

After cleaning and surface preparation, the hull is treated with:

- Anti-corrosive coatings

- Anti-fouling paints

- Specialized offshore coatings for harsh conditions

Correct coating selection prevents corrosion and reduces long-term maintenance costs.

6. Structural & Mechanical Repairs

Dry dock allows access to critical systems including:

- Ballast tanks

- Rudder & steering gear

- Sea chests

- Bow thrusters

- Pipelines

- Sea-water strainers

Any deformed, corroded, or worn components are repaired or replaced.

7. Class Surveys & Testing

Vessels must comply with class society requirements.

During dry docking, surveyors perform checks such as:

- Ultrasonic thickness measurement

- Shaft & propeller clearance tests

- Rudder drop measurement

- Sea valve overhaul verification

- Hull integrity inspection

Proper documentation is provided for classification renewal.

8. Re-Floating & Sea Trials

After all works are completed:

- The dock is flooded

- The vessel is re-aligned and floated out

- Sea trials verify propulsion, steering, and vibration levels

This ensures the ship is ready for safe operational service.

Why Dry Docking Should Never Be Delayed

Ignoring dry docking schedules leads to:

- Severe underwater corrosion

- Propeller imbalance

- Premature bearing failure

- Reduced fuel efficiency

- Increased downtime

- Safety hazards

In several industry studies, vessels that skip scheduled dry docking face up to 30% higher long-term maintenance costs.

How NASS Engineering Supports Complete Dry Dock Projects

With extensive experience in commercial, offshore, and defence vessels, NASS provides:

• Complete Dry Dock Project Execution

End-to-end management from arrival to sea trials.

• Propulsion System Overhaul

CPP/FPP, shafts, gearboxes, thrusters, and waterjets.

• Structural & Mechanical Repairs

Hull work, steel renewal, piping, rudder systems, and underwater fittings.

• Electrical & Equipment Upgrades

Navigation, fire systems, automation, HVAC, and power systems.

• Coating & Anti-Fouling Solutions

High-performance marine coatings for long-term hull protection.

• Compliance Support

Coordination with Class surveyors, documentation, and certification support.

Best Practices for a Successful Dry Dock

As marine research and engineering experts, we recommend:

1. Always conduct pre-dock inspection

It ensures accurate planning and reduces delays.

2. Assign certified specialists

Propulsion and hull work require trained engineers.

3. Use genuine parts

Propeller seals, bearings, shafts, and blades must be OEM-grade.

4. Monitor dock block alignment

Incorrect alignment can cause hull distortion.

5. Maintain a performance log

Track vibration, thrust, and fuel efficiency post-dry dock.

Conclusion — Dry Docking Protects Your Vessel’s Future

Dry docking is not just mandatory — it is essential for ensuring:

- Safe operations

- Lower operating costs

- Better fuel efficiency

- Longer equipment life

- Compliance with global marine standards

With the right engineering expertise, vessels achieve peak performance and reliability after every dry dock cycle.

For trusted, certified, and technically advanced dry docking support, NASS Engineering Services Pvt. Ltd. stands as a proven marine engineering partner.