Electro-Motive Diesel (EMD) engines are widely used in marine propulsion and power generation applications where reliability, high load endurance, and long operating cycles are required. These engines are commonly found in offshore vessels, tugs, defense platforms, and power barges operating under demanding conditions.

Despite their rugged design, EMD marine engines require structured maintenance, accurate diagnostics, and timely overhaul to deliver consistent performance over long service lives. From a marine engineering perspective, most EMD engine failures are progressive and preventable when detected early.

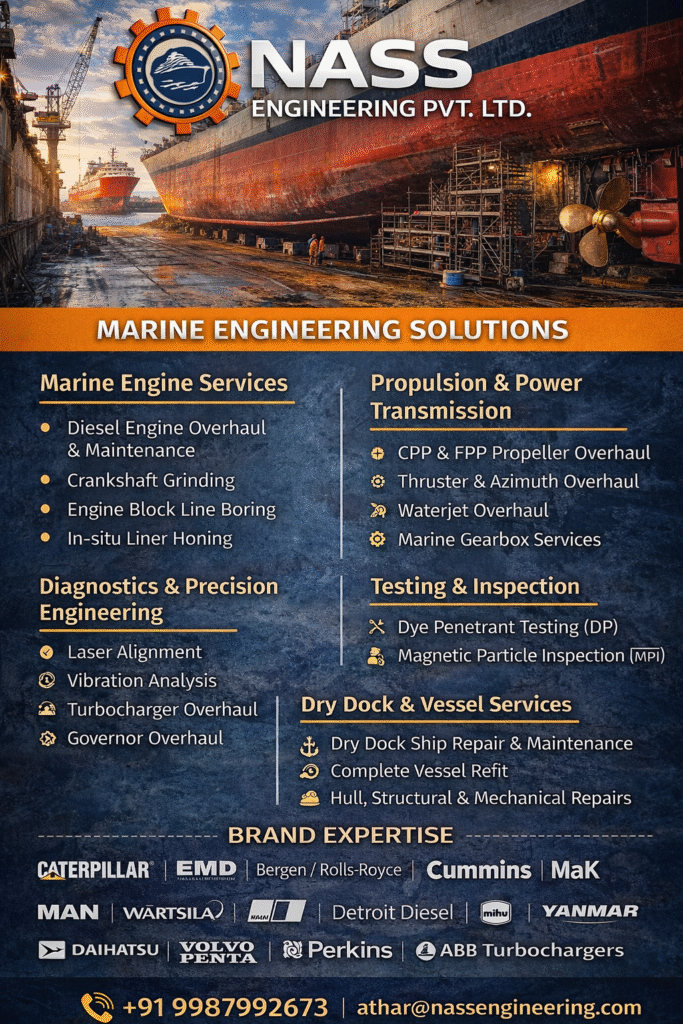

At NASS Engineering Services Pvt. Ltd., we provide professional EMD marine engine repair, servicing, and overhaul support for vessels operating globally.

Overview of EMD Marine Engines

EMD marine engines are medium-speed, two-stroke or four-stroke diesel engines designed for continuous-duty marine environments.

Key Characteristics

- High power output with steady torque delivery

- Robust crankcase and bearing design

- Long overhaul intervals when properly maintained

- Proven performance in harsh offshore conditions

These engines are engineered for reliability but are highly sensitive to fuel quality, lubrication condition, and alignment accuracy.

Typical Applications of EMD Marine Engines

EMD engines are commonly used in:

- Offshore support vessels

- Harbor and ocean-going tugs

- Naval and coast guard vessels

- Power barges and auxiliary power systems

- Heavy-duty workboats

These applications expose engines to variable loads, frequent starts and stops, and extended operating hours.

Importance of Structured Maintenance for EMD Engines

Routine maintenance is critical for preventing progressive wear and avoiding unplanned shutdowns.

Daily and Routine Checks

- Lubricating oil pressure and temperature monitoring

- Fuel system inspection for leaks and contamination

- Cooling water flow and temperature checks

- Exhaust temperature trend monitoring

- Visual inspection for vibration or abnormal noise

Consistent monitoring helps identify early warning signs before mechanical damage occurs.

Scheduled Maintenance Requirements

Fuel System Maintenance

Fuel injectors and pumps must be inspected and calibrated at defined intervals.

Poor fuel quality or delayed injector servicing leads to:

- Incomplete combustion

- Excessive exhaust smoke

- Higher fuel consumption

- Piston and liner wear

Lubrication System Maintenance

Lubrication failures are among the most common causes of major EMD engine damage.

Key maintenance actions include:

- Oil analysis at regular intervals

- Filter replacement as per operating hours

- Maintaining correct oil grade and viscosity

- Monitoring bearing temperature trends

Clean and stable lubrication significantly extends bearing and crankshaft life.

Cooling System Maintenance

Cooling efficiency directly affects engine reliability.

Maintenance activities include:

- Heat exchanger cleaning

- Seawater pump inspection

- Thermostat and valve checks

- Monitoring jacket water temperatures

Overheating accelerates wear and increases the risk of bearing and piston damage.

Common Failure Modes in EMD Marine Engines

Even well-maintained engines can develop faults over time. Understanding these failure modes helps prevent escalation.

Bearing Wear and Failure

Primary Causes

- Oil contamination

- Incorrect oil grade

- Prolonged operation at overload

- Misalignment between engine and gearbox

Warning Signs

- Rising oil temperature

- Metallic particles in oil

- Increased vibration

- Audible knocking

Bearing failures often begin gradually and become catastrophic if ignored.

Fuel Injection System Issues

Primary Causes

- Contaminated fuel

- Injector nozzle wear

- Incorrect timing

Warning Signs

- Smoke increase

- Uneven cylinder load

- Power loss

- Poor throttle response

Early injector servicing prevents piston crown damage.

Cooling-Related Failures

Primary Causes

- Fouled heat exchangers

- Restricted seawater flow

- Pump wear

Warning Signs

- High jacket water temperature

- Repeated temperature alarms

- Load reduction under operation

Vibration and Alignment Problems

Primary Causes

- Engine to gearbox misalignment

- Worn engine mounts

- Propeller imbalance

Warning Signs

- Elevated vibration readings

- Seal leakage

- Premature bearing wear

Alignment issues often originate outside the engine but cause internal damage over time.

EMD Engine Overhaul — What It Involves

Top Overhaul

A top overhaul typically includes:

- Cylinder head inspection and servicing

- Injector replacement or calibration

- Valve and seat inspection

- Piston crown inspection

- Gasket and seal renewal

Top overhauls restore combustion efficiency and prevent deeper mechanical damage.

Major Overhaul

A major overhaul includes:

- Crankshaft inspection and measurement

- Main and connecting rod bearing replacement

- Liner and piston replacement

- Fuel system calibration

- Complete reassembly with tolerance checks

Major overhauls must follow OEM specifications and documented clearances.

Role of Diagnostics in EMD Engine Reliability

Modern maintenance relies heavily on predictive diagnostics.

Key Diagnostic Tools

- Vibration analysis

- Laser alignment

- Oil analysis

- Exhaust temperature trending

These tools allow maintenance to be planned rather than reactive.

Spare Parts and Quality Considerations

Using incorrect or sub-standard spare parts results in:

- Reduced component life

- Incorrect tolerances

- Seal failures

- Increased overhaul frequency

EMD engines require precision-manufactured components to maintain performance and reliability.

When to Schedule EMD Engine Repair or Overhaul

Typical indicators include:

- Drop in power output

- Increased oil consumption

- Persistent smoke

- Abnormal vibration levels

- Repeated injector failures

- Metal contamination in oil

Timely intervention significantly reduces repair costs.

How NASS Engineering Supports EMD Marine Engines

NASS Engineering Services Pvt. Ltd. provides:

- Complete EMD marine engine repair and overhaul

- Fuel injector and pump servicing

- Bearing inspection and replacement

- Crankshaft inspection and alignment

- Vibration analysis and laser alignment

- Onboard troubleshooting and sailing attendance

- Genuine spare parts support

Our engineers follow structured procedures aligned with ISO-certified quality standards.

Conclusion

EMD marine engines are built for durability, but their reliability depends on disciplined maintenance, accurate diagnostics, and timely overhaul. Most failures develop progressively and can be avoided through early detection and professional servicing.

With proven experience in EMD engine repair and overhaul, NASS Engineering Services Pvt. Ltd. supports vessel operators with reliable, technically sound marine engineering solutions.