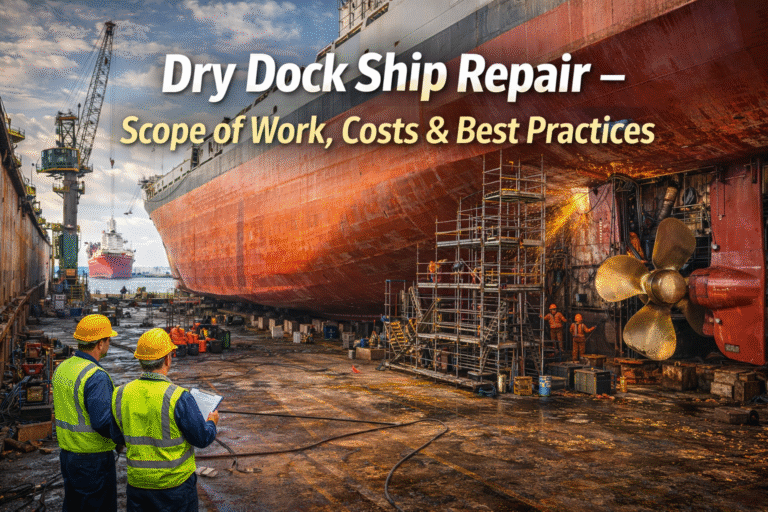

Dry dock ship repair is a critical activity in a vessel’s lifecycle where structural, mechanical, and propulsion-related issues are addressed in a controlled environment. Unlike routine onboard maintenance, dry dock repair allows full access to the hull and underwater systems, making it the most effective phase for executing complex and heavy repairs.

From a marine engineering perspective, dry dock repair is not just about fixing visible damage. It is about restoring vessel integrity, ensuring regulatory compliance, improving operational efficiency, and preventing future failures.

This guide explains the typical scope of dry dock ship repair, key cost drivers, and best practices followed by experienced marine engineering teams.

What Is Dry Dock Ship Repair

Dry dock ship repair refers to corrective and renewal work carried out when a vessel is taken out of the water and positioned in a dry dock facility. Once dewatered, engineers can inspect, repair, and replace components that are otherwise inaccessible during normal operation.

Dry dock repairs are typically carried out:

- During scheduled class surveys

- When damage or excessive wear is identified

- As part of major refit or life-extension projects

Effective repair planning during dry dock directly affects vessel reliability and downtime.

Understanding the dry docking process helps vessel owners plan repair scope, timelines, and resource allocation more effectively.

Typical Scope of Work in Dry Dock Ship Repair

The scope of repair work varies based on vessel type, age, operating conditions, and regulatory requirements.

Effective dry dock ship maintenance planning ensures that repair activities are executed efficiently without unnecessary delays or cost escalation.

However, most dry dock ship repair projects include the following areas.

Hull and Structural Repairs

Common Hull Repairs

- Steel renewal in corroded areas

- Crack detection and welding

- Dent and deformation correction

- Shell plating repair

- Structural reinforcement

Hull repairs restore strength and prevent progressive corrosion damage.

Inspection Activities

- Visual inspection

- Ultrasonic thickness measurements

- Non-destructive testing where required

Propulsion System Repairs

Propulsion-related repairs form a major part of dry dock ship repair. Dry dock repair is the most suitable time to carry out comprehensive propulsion system maintenance, including inspection of shafts, bearings, and propellers.

Propellers

- Blade crack repair

- Cavitation damage correction

- Blade straightening

- Pitch adjustment for CPP systems

Timely propeller repair during dry dock helps eliminate vibration issues and restores propulsion efficiency.

Shafting and Stern Gear

- Shaft inspection and polishing

- Bearing inspection and renewal

- Stern tube seal replacement

- Alignment correction

Neglecting propulsion repairs during dry dock often results in vibration and early bearing failures.

Main Engine and Machinery Repairs

Dry dock provides an opportunity to carry out repairs that are difficult or risky at sea. Dry dock periods are ideal for planned marine engine overhaul, allowing major repairs to be completed safely and efficiently.

Main Engines

- Cooling system repair

- Turbocharger overhaul

- Exhaust system repair

- External leak rectification

Auxiliary Machinery

- Generator repair and servicing

- Pump overhaul

- Compressor maintenance

- Heat exchanger cleaning and repair

Machinery reliability after dry dock depends on repair quality and proper testing.

Steering Gear and Rudder Repairs

Steering failures can compromise vessel safety.

Typical Repairs

- Rudder stock inspection

- Pintle and bearing renewal

- Seal replacement

- Hydraulic system repairs

These repairs are best handled when the vessel is fully accessible in dry dock.

Tank Repairs and Internal Structure Work

Ballast and Fuel Tanks

- Corrosion repair

- Coating renewal

- Structural reinforcement

- Leakage rectification

Void Spaces

- Internal inspection

- Coating repairs

- Structural crack repair

Tank repairs are often overlooked but critical for long-term vessel integrity.

Coating and Surface Protection Repairs

Coating work protects the vessel from corrosion and fouling.

Repair Scope

- Surface preparation

- Spot coating or full coating renewal

- Anti-fouling application

- Anode replacement

Quality coating work directly impacts fuel efficiency and hull life.

Key Cost Factors in Dry Dock Ship Repair

Understanding repair cost drivers helps vessel owners plan budgets effectively.

Major Cost Influencers

- Extent of steel renewal required

- Condition of propulsion components

- Machinery repair scope

- Coating system selection

- Dock occupancy duration

- Labor and material availability

Unexpected findings during inspection often increase repair costs.

Common Reasons Dry Dock Repair Costs Escalate

- Inadequate pre-dock inspection

- Poor scope definition

- Delayed spare parts procurement

- Additional class requirements

- Unplanned structural damage discovery

Proper engineering planning reduces financial surprises.

Best Practices for Successful Dry Dock Ship Repair

Plan Repairs Well in Advance

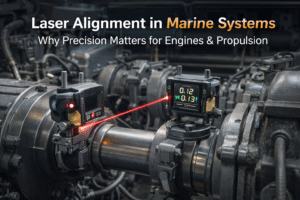

Early planning allows accurate scope definition, spare parts procurement, and coordination with class surveyors. Performing vibration analysis after dry dock repair confirms correct alignment, balance, and installation quality.

Define Repair Scope Clearly

A well-defined scope avoids confusion and prevents uncontrolled work additions during docking.

Use Qualified Marine Engineering Teams

Experienced engineers ensure repairs are executed to correct tolerances and standards.

Maintain Quality Control

Regular inspections during repair work help identify issues early and maintain repair quality.

Conduct Thorough Post-Repair Testing

Alignment checks, leak tests, and functional trials must be completed before vessel re-entry into service.

Dry Dock Ship Repair vs Routine Maintenance

| Aspect | Dry Dock Repair | Routine Maintenance |

|---|---|---|

| Vessel condition | Out of water | In service |

| Repair scope | Structural and heavy repairs | Minor servicing |

| Accessibility | Full access | Limited |

| Cost | Higher | Lower |

| Impact | Long-term reliability | Short-term operation |

Both are necessary, but dry dock repair plays a decisive role in vessel longevity.

When Should Dry Dock Ship Repair Be Scheduled

Repair work should be planned when:

- Class surveys are due

- Repeated failures occur

- Corrosion exceeds acceptable limits

- Propulsion vibration increases

- Machinery reliability declines

Delaying repairs often increases total lifecycle costs. Precision laser alignment during reinstallation reduces bearing loads and prevents premature propulsion failures.

How Professional Dry Dock Repair Adds Value

Professionally executed dry dock repairs result in:

- Reduced unplanned downtime

- Improved vessel performance

- Longer maintenance intervals

- Better fuel efficiency

- Compliance with regulatory standards

Quality repairs protect both safety and investment.

Conclusion

Dry dock ship repair is a complex engineering activity that requires detailed planning, skilled execution, and strict quality control. Addressing structural, propulsion, and machinery issues at the right time prevents escalation and ensures reliable vessel operation.

By following best practices and engaging experienced marine engineering support, dry dock repair becomes a strategic investment rather than a reactive expense.