Dry dock planning is the most decisive phase in a vessel’s maintenance cycle. Long before a ship enters the dock, the quality of planning determines whether the dry dock period will be efficient, cost-controlled, and technically successful, or delayed, over-budget, and reactive.

From a marine engineering perspective, dry dock planning is not an administrative task. It is a structured technical process that aligns vessel condition, repair scope, timelines, manpower, and compliance requirements into a single executable plan.

This guide explains how professional dry dock planning is carried out, what engineering inputs are required, and how risks and delays can be controlled before docking begins.

Why Dry Dock Planning Is Critical

Most dry dock failures do not occur inside the dock. They originate weeks or months earlier due to poor preparation.

Inadequate planning leads to:

- Unclear repair scope

- Delayed spare parts

- Unplanned additional work

- Extended dock occupancy

- Cost escalation

- Compromised repair quality

Well-planned dry docking, on the other hand, allows vessel owners to control cost, reduce downtime, and return the ship to service with predictable performance. A clear understanding of the dry docking process allows planners to align technical scope, timelines, and resources well before the vessel enters dock.

Pre-Dry Dock Engineering Assessment

Dry dock planning begins with understanding the true condition of the vessel.

Hull and Structural Assessment

Before docking, engineers should review:

- Previous dry dock reports

- Known corrosion zones

- Past steel renewal history

- Class remarks and conditions

Where required, preliminary underwater inspections help identify potential structural work and steel renewal needs.

Machinery Health Review

Machinery planning is often underestimated during dry dock preparation.

Engineering review should include:

- Main engine running hours and service history

- Auxiliary machinery performance

- Cooling system efficiency trends

- Exhaust temperature patterns

- Lubrication and oil analysis records

This allows maintenance tasks to be planned instead of discovered late. Accurate assessment ensures that major tasks such as marine engine overhaul are planned rather than discovered during dock inspection.

Propulsion and Performance Data Review

Planning should consider:

- Vibration history

- Alignment records

- Propeller and shaft condition trends

- Thruster or waterjet performance data

Using existing performance data reduces surprises during inspection. Reviewing historical data allows planners to schedule critical propulsion system maintenance without disrupting the dry dock timeline.

Dry Dock Scope Definition

Clear scope definition is the backbone of dry dock planning.

Mandatory Scope

This includes:

- Class survey requirements

- Statutory inspections

- Regulatory compliance items

- Due maintenance tasks

These items are non-negotiable and must be planned early. Planning decisions directly influence the effectiveness of subsequent dry dock ship maintenance activities carried out during execution.

Optional and Preventive Scope

Engineering teams should also identify:

- Preventive repairs

- Reliability improvements

- Known weak points

- Life-extension opportunities

Including preventive work during planned docking is almost always more economical than emergency repairs later.

Scope Prioritization

Not all work carries equal risk.

Critical items should be prioritized based on:

- Safety impact

- Operational reliability

- Failure probability

- Cost of deferral

This ensures limited dock time is used effectively.

Dry Dock Timeline Planning

Time management is one of the most sensitive aspects of dry dock planning.

Pre-Dock Timeline

Planning should begin well in advance and include:

- Engineering assessment window

- Spare parts procurement lead times

- Contractor availability

- Class surveyor coordination

Late planning almost always results in schedule compression and errors.

Docking Phase Timeline

The docking period itself should be broken into phases:

- Docking and dewatering

- Inspection and measurement

- Repair execution

- Reinstallation and alignment

- Testing and commissioning

Each phase should have clear responsibility and sequencing.

Buffer and Contingency Planning

Engineering-led planning always includes buffers for:

- Unexpected findings

- Additional class requirements

- Weather delays

- Material replacement

Ignoring contingencies leads to unrealistic schedules.

Risk Identification and Control

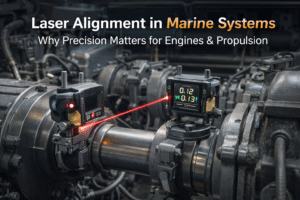

Risk management is a key differentiator between average and professional dry dock planning. Planning for precision laser alignment during reinstallation minimizes bearing stress and reduces the risk of premature failures after docking.

Common Dry Dock Risks

Typical risks include:

- Discovery of hidden corrosion

- Spare parts delays

- Interface issues between contractors

- Rework due to poor coordination

- Alignment and vibration problems post-dock

Most of these risks are predictable with experience. Incorporating post-repair vibration analysis into the plan helps verify alignment quality and detect hidden installation issues early.

Risk Mitigation Strategies

Effective mitigation includes:

- Early inspections

- Advance spares planning

- Clear work sequencing

- Defined inspection hold points

- Post-repair validation planning

Engineering involvement at the planning stage reduces reactive decision-making.

Cost Planning and Budget Control

Dry dock cost overruns usually stem from scope uncertainty.

Planned vs Unplanned Cost

Planned costs are predictable.

Unplanned costs emerge from:

- Late scope additions

- Emergency repairs

- Extended dock stay

- Rework and delays

Dry dock planning aims to convert unplanned cost into planned cost. Well-defined planning significantly reduces unexpected work during dry dock ship repair, helping control both timelines and overall cost.

Engineering-Driven Cost Optimization

Cost control does not mean cutting work.

It means:

- Doing the right work at the right time

- Avoiding duplication

- Preventing repeat failures

- Using dock access efficiently

Quality planning reduces total lifecycle cost.

Role of Engineering Partners in Dry Dock Planning

Dry dock planning benefits significantly from early involvement of experienced marine engineering teams.

Engineering partners contribute by:

- Reviewing technical data

- Identifying failure trends

- Advising on repair sequencing

- Planning diagnostics and validation

- Coordinating technical interfaces

Early engineering input reduces execution-stage surprises.

Best Practices for Successful Dry Dock Planning

From field experience, the following practices consistently improve outcomes:

- Start planning early

- Base scope on data, not assumptions

- Align scope with class requirements

- Secure critical spares in advance

- Define inspection and approval points

- Plan post-dock validation activities

- Assign clear technical responsibility

Dry dock success is decided on paper before steel is cut.

Relationship Between Planning and Execution

Dry dock planning does not replace execution.

It enables it.

Well-planned docking leads to:

- Smoother maintenance execution

- Fewer interruptions

- Better quality repairs

- Faster return to service

- Predictable performance after docking

Execution quality reflects planning quality.

Conclusion

Dry dock planning for ships is a technical discipline, not a scheduling exercise. It combines engineering assessment, scope definition, timeline control, and risk management into a structured process that protects both vessel performance and investment.

When planning is approached systematically and supported by engineering expertise, dry docking becomes a controlled maintenance activity rather than a reactive repair event.

Strong dry dock planning is the foundation of reliable ship operations.