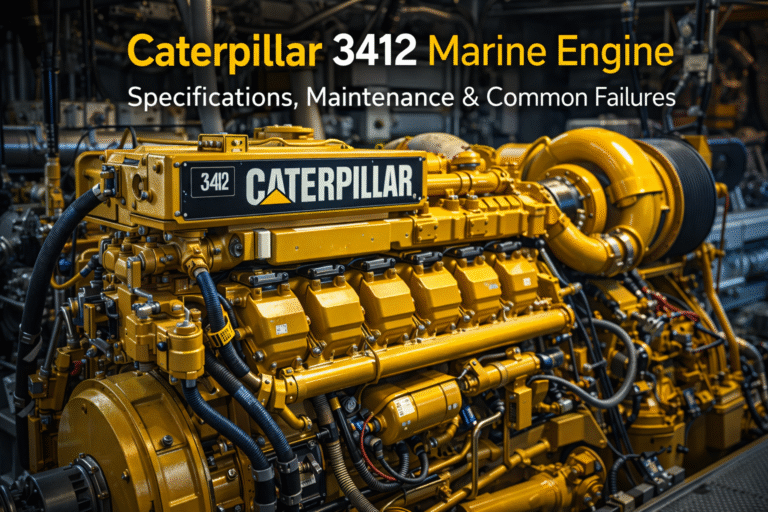

The Caterpillar 3412 marine engine is one of the most widely used high-power diesel engines in commercial, offshore, and defense vessels. Known for its reliability and high torque output, the 3412 has powered tugs, patrol vessels, offshore support ships, and workboats across the world for decades.

However, long service life depends heavily on correct operation, timely maintenance, and proper overhaul practices. From a marine engineering perspective, understanding the technical characteristics and known failure patterns of the CAT 3412 is critical for preventing downtime and extending engine life.

At NASS Engineering Services Pvt. Ltd., we regularly service, overhaul, and support CAT 3412 engines in demanding marine environments.

Overview of the Caterpillar 3412 Marine Engine

The CAT 3412 is a 12-cylinder, V-configuration, four-stroke diesel engine designed for continuous marine duty. It is commonly used where high power density and durability are required.

Basic Engine Configuration

- Engine type: V12, four-stroke diesel

- Aspiration: Turbocharged and aftercooled

- Fuel system: Mechanical or electronic fuel injection (variant dependent)

- Cooling system: Heat exchanger or keel-cooled

- Application: Propulsion and auxiliary marine power

The engine is known for its strong mid-range torque, which makes it suitable for heavy displacement vessels and maneuver-intensive operations.

Typical Applications of CAT 3412 Marine Engines

CAT 3412 engines are commonly found in:

- Offshore supply vessels

- Tugs and workboats

- Patrol and coast guard vessels

- Research and survey vessels

- Crew transfer vessels

- Power generation onboard ships

These applications expose the engine to variable loads, frequent speed changes, and long operating hours.

Key Technical Strengths of the CAT 3412

From an engineering standpoint, the 3412 gained popularity because of several design advantages.

High Torque Output

The V12 configuration delivers strong torque at lower RPM, which is ideal for propulsion duties.

Robust Block and Crankshaft Design

Heavy-duty construction allows the engine to withstand continuous marine loads.

Serviceability

Modular design makes maintenance and overhaul relatively straightforward compared to many modern engines.

Global Parts Availability

Spare parts and technical support are widely available, making lifecycle maintenance manageable.

Recommended Maintenance Practices for CAT 3412

Proper maintenance is the single most important factor in extending the service life of a CAT 3412 marine engine.

Routine Maintenance

- Regular oil and filter changes based on running hours

- Fuel filter replacement and water separation checks

- Cooling system inspection and flushing

- Valve clearance inspection at recommended intervals

- Turbocharger inspection for fouling or imbalance

Neglecting basic service routines is the most common cause of premature failure.

Top Overhaul Requirements

A top overhaul typically includes:

- Cylinder head removal and inspection

- Injector testing or replacement

- Valve, seat, and guide inspection

- Piston crown and liner inspection

- Gasket and seal replacement

Top overhauls help restore combustion efficiency and prevent deeper mechanical damage.

Major Overhaul Requirements

A major overhaul involves:

- Crankshaft inspection and grinding if required

- Bearing replacement

- Connecting rod inspection

- Full liner and piston replacement

- Complete fuel system calibration

Major overhauls should always follow OEM specifications and documented tolerances.

Common Failure Points in CAT 3412 Marine Engines

Despite its reliability, the CAT 3412 has known failure patterns when maintenance is delayed or operating conditions are poor.

Fuel Injector and Fuel Pump Wear

Why it happens

- Contaminated fuel

- Extended injector service intervals

- Improper calibration

Symptoms

- Black or white smoke

- Poor throttle response

- Increased fuel consumption

- Rough engine operation

Fuel injection issues directly affect combustion efficiency and engine life.

Cooling System Failures

Why it happens

- Blocked heat exchangers

- Scale buildup

- Seawater pump wear

- Low coolant flow

Symptoms

- Elevated engine temperatures

- Alarm activation

- Loss of power under load

Overheating accelerates oil breakdown and bearing wear.

Bearing and Lubrication Failures

Why it happens

- Low oil pressure

- Contaminated oil

- Incorrect oil grade

- Extended oil change intervals

Symptoms

- Knocking sounds

- Metal particles in oil

- Rising vibration levels

Lubrication failure is one of the costliest and most destructive failure modes.

Turbocharger Issues

Why it happens

- Oil starvation

- Carbon buildup

- Rotor imbalance

- Excessive exhaust temperatures

Symptoms

- Loss of boost pressure

- Blue or black smoke

- High exhaust temperature readings

Turbocharger health is directly linked to engine performance.

Vibration and Misalignment Problems

Why it happens

- Poor engine to gearbox alignment

- Worn engine mounts

- Propeller imbalance

Symptoms

- Elevated vibration

- Premature bearing failure

- Seal leakage

Alignment errors often originate outside the engine but cause internal damage over time.

Operating Practices That Extend Engine Life

From marine research and field experience, the following practices significantly improve reliability.

- Avoid prolonged low-load operation

- Allow proper warm-up before high load

- Follow controlled cool-down procedures

- Monitor exhaust temperatures

- Track vibration trends

- Maintain accurate service logs

Engines fail faster due to poor operation than due to design limitations.

Spare Parts and Component Quality Considerations

Using incorrect or sub-standard spare parts introduces:

- Poor tolerances

- Premature wear

- Seal failures

- Reduced overhaul life

CAT 3412 engines require precision-manufactured components to maintain compression, lubrication integrity, and fuel efficiency.

When Should a CAT 3412 Be Overhauled

Typical indicators include:

- Drop in power output

- Rising oil consumption

- Persistent smoke

- High vibration levels

- Metal contamination in oil

- Repeated injector failures

Delaying overhaul after these signs appear significantly increases repair costs.

How NASS Engineering Supports CAT 3412 Engines

NASS Engineering Services Pvt. Ltd. provides:

- Complete CAT 3412 engine overhauls

- Fuel injector and pump servicing

- Turbocharger overhaul

- Crankshaft grinding and line boring

- Vibration analysis and laser alignment

- Onboard troubleshooting and sailing attendance

- Genuine spare parts support

Our teams follow structured procedures backed by ISO-certified quality systems.

Conclusion

The Caterpillar 3412 marine engine remains a powerful and reliable choice when maintained correctly. Most failures are not sudden. They develop gradually through fuel, lubrication, cooling, or alignment issues.

With proper servicing, correct operating practices, and timely overhaul, a CAT 3412 can deliver decades of dependable marine service.

For professional inspection, overhaul, and long-term support of CAT 3412 engines, NASS Engineering Services Pvt. Ltd. provides proven marine engineering expertise.