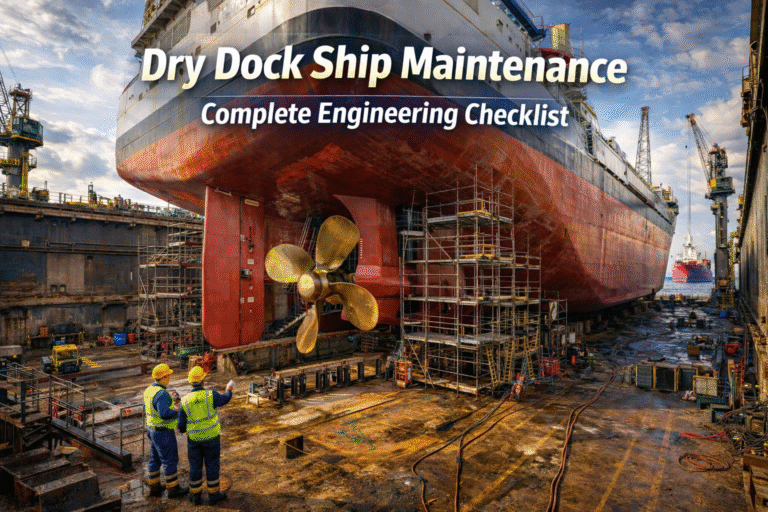

Dry dock ship maintenance is one of the most critical phases in a vessel’s operational lifecycle. It is the only time when the hull, underwater systems, propulsion components, and structural elements are fully accessible for inspection, repair, and renewal.

From an engineering perspective, dry docking is not just about compliance. It is about restoring efficiency, preventing failures, controlling long-term costs, and ensuring vessel safety.

This checklist-driven guide explains what needs to be maintained before, during, and after dry docking, based on real marine engineering practices.

Why Dry Dock Ship Maintenance Is So Important

Every vessel operating at sea is continuously exposed to corrosion, fouling, mechanical stress, and wear. Over time, even minor issues develop into major failures if left unaddressed.

Understanding the dry docking process is essential to ensure that ship maintenance activities are planned, executed, and verified correctly during a scheduled dock period.

Proper dry dock maintenance helps to:

- Improve fuel efficiency

- Extend machinery and hull life

- Reduce vibration and noise

- Prevent unplanned breakdowns

- Ensure compliance with class and statutory requirements

Well-planned dry dock maintenance directly impacts vessel availability and operating costs.

Pre-Dry Dock Maintenance Checklist

Planning before the vessel enters dry dock is the most important phase. Poor preparation often leads to delays, cost overruns, and incomplete work.

Hull and Structural Preparation

- Review previous dry dock reports

- Identify known corrosion areas

- Plan steel renewal if required

- Prepare hull inspection scope

Machinery and Propulsion Planning

- Review engine running hours

- Identify engines or auxiliaries due for overhaul

- Prepare scope for propellers, shafts, thrusters, and gearboxes

- Confirm spare parts availability

Documentation and Class Requirements

- Coordinate with class surveyors

- Prepare inspection checklists

- Identify mandatory surveys and measurements

- Align dry dock schedule with class due dates

Dry Dock Hull Maintenance Checklist

Once the vessel is docked and dewatered, hull inspection and treatment become the first priority.

Hull Inspection

- Visual inspection of underwater hull

- Identification of cracks, dents, or deformation

- Ultrasonic thickness measurement where required

- Inspection of sea chests and gratings

Hull Cleaning and Surface Preparation

- High-pressure water blasting

- Removal of marine growth

- Surface preparation for coating application

Coating and Protection

- Application of anti-corrosion coatings

- Application of anti-fouling systems

- Inspection of sacrificial anodes

- Replacement or renewal of cathodic protection

A well-maintained hull can improve fuel efficiency by a significant margin.

Propulsion System Maintenance Checklist

Dry docking provides full access to propulsion systems, making this the ideal time for inspection and corrective work.

Propellers

- Visual inspection for cracks and deformation

- Blade surface inspection for cavitation damage

- Pitch measurement for CPP systems

- Dynamic balancing if required

Early identification of propeller damage and repair requirements during dry dock helps prevent vibration issues and propulsion inefficiencies once the vessel returns to service.

Shafting and Bearings

- Shaft alignment checks

- Bearing clearance measurement

- Stern tube inspection

- Seal condition assessment

Precision laser alignment during dry dock reduces bearing loads, seal wear, and long-term propulsion system stress.

Thrusters and Waterjets

- Gear inspection

- Bearing and seal inspection

- Oil condition check

- Functional testing after reinstallation

Ignoring propulsion maintenance during dry dock often leads to vibration and premature failures later.

Main Engine and Auxiliary Maintenance Checklist

Main Engines

- External inspection for leaks and vibration

- Cooling system cleaning

- Exhaust system inspection

- Turbocharger inspection

- Fuel and lubrication system checks

Auxiliary Systems

- Generator inspection and servicing

- Pumps and compressors inspection

- Heat exchangers cleaning

- Valves and piping inspection

Dry docking allows heavy maintenance without operational pressure. Dry dock periods are ideal for planned marine engine overhaul, allowing major maintenance work without operational pressure.

Steering Gear and Rudder Maintenance Checklist

- Rudder stock inspection

- Rudder clearance measurement

- Pintle and bearing inspection

- Steering gear hydraulic system inspection

- Seal replacement if required

Steering system reliability is critical for vessel safety and maneuverability.

Tank and Internal Structure Maintenance

Ballast and Fuel Tanks

- Internal inspection

- Corrosion assessment

- Coating condition check

- Thickness measurement if required

Void Spaces

- Structural inspection

- Coating repair

- Drain and ventilation check

Tank maintenance is often overlooked but critical for structural integrity.

Electrical and Safety System Maintenance

- Cable inspection in exposed areas

- Earthing and bonding checks

- Navigation light inspection

- Fire detection and alarm systems

- Emergency equipment verification

Dry dock is the safest environment for electrical inspections.

Post-Dry Dock Checks Before Sailing

Before the vessel is refloated and returns to service, final checks are essential. Conducting vibration analysis after dry dock maintenance ensures that alignment, balancing, and machinery installation have been executed correctly.

- Recheck shaft alignment

- Verify propulsion system performance

- Test steering and maneuvering systems

- Check vibration levels

- Confirm leak-free operation

- Complete class and regulatory documentation

Sea trials validate the quality of dry dock maintenance.

Common Dry Dock Maintenance Mistakes to Avoid

- Inadequate pre-dock planning

- Delaying spare parts procurement

- Ignoring alignment and vibration checks

- Using non-genuine components

- Rushing post-dock inspections

Avoiding these mistakes saves time and cost in the long run.

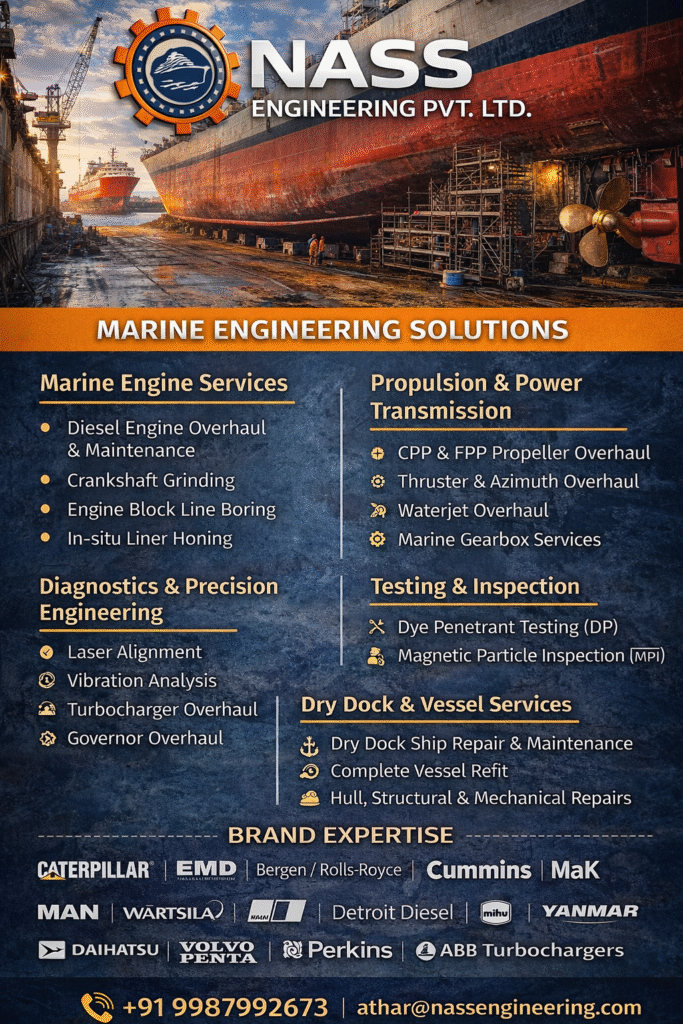

How Professional Dry Dock Maintenance Adds Value

Professional dry dock execution ensures:

- Reduced operational downtime

- Improved vessel performance

- Lower fuel consumption

- Extended overhaul intervals

- Predictable maintenance costs

Engineering-driven maintenance always outperforms reactive repairs.

Conclusion

Dry dock ship maintenance is not just a routine requirement. It is a strategic opportunity to restore vessel performance, prevent failures, and extend service life.

A structured checklist approach ensures that no critical system is overlooked and that the vessel returns to service in optimal condition.

With experienced marine engineering support, dry dock maintenance becomes a long-term investment rather than an operational disruption.