In modern marine engineering, failures rarely happen without warning.

Most mechanical breakdowns begin as small, measurable changes in vibration patterns long before visible damage occurs.

Vibration analysis is one of the most powerful diagnostic tools used today to detect early-stage faults in marine engines, gearboxes, shafts, thrusters, and propulsion systems. When applied correctly, it allows operators to fix problems before they become failures.

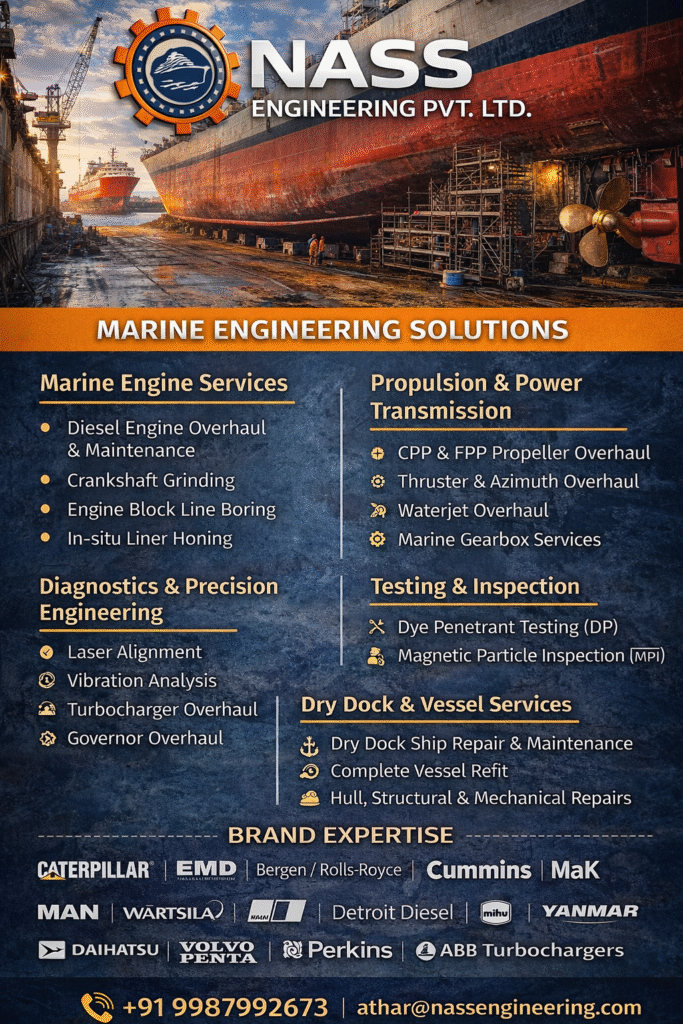

At NASS Engineering Services Pvt. Ltd., vibration analysis is a core part of our predictive maintenance approach for marine, offshore, power, and defence vessels.

What Is Vibration Analysis in Marine Engineering?

Vibration analysis is the process of measuring and interpreting mechanical vibrations generated by rotating and reciprocating equipment.

Every machine vibrates.

The pattern, frequency, and amplitude of vibration reveal the condition of internal components.

By analyzing these signals, engineers can identify:

- Imbalance

- Misalignment

- Bearing wear

- Gear defects

- Shaft damage

- Looseness

- Structural resonance

This makes vibration analysis a non-invasive, real-time health check for marine machinery.

Why Vibration Matters in Marine Systems

Marine engines and propulsion systems operate under:

- Continuous load

- Variable speeds

- High torque

- Corrosive environments

- Long running hours

These conditions accelerate wear.

Unchecked vibration leads to:

- Bearing failure

- Shaft fatigue

- Seal damage

- Cracked foundations

- Gear tooth damage

- Increased fuel consumption

Controlling vibration directly improves reliability and efficiency.

Key Marine Equipment That Requires Vibration Monitoring

Vibration analysis is especially critical for:

• Marine Diesel Engines

Detects imbalance, combustion issues, and crankshaft problems.

• Gearboxes

Identifies gear mesh faults, misalignment, and bearing wear.

• Propulsion Shafts

Detects bent shafts, misalignment, and coupling issues.

• Thrusters (Bow & Azimuth)

Identifies bearing wear, seal damage, and gear defects.

• Waterjet Systems

Detects pump imbalance and cavitation-related issues.

• Turbochargers

Identifies rotor imbalance and bearing degradation.

Common Marine Faults Detected Through Vibration Analysis

1. Shaft Misalignment

One of the most common and destructive issues.

Symptoms detected:

- High axial vibration

- Increased bearing temperature

- Seal leakage

Misalignment accelerates bearing and seal failure if left uncorrected.

2. Rotational Imbalance

Occurs due to uneven mass distribution.

Detected by:

- High vibration at running speed (1× RPM)

- Increased stress on bearings and shafts

Balancing corrects this before damage spreads.

3. Bearing Wear and Failure

Bearings fail gradually and predictably.

Vibration analysis detects:

- Early-stage bearing defects

- Lubrication issues

- Surface fatigue

This allows replacement before seizure occurs.

4. Gear Defects

Gear wear is common in propulsion gearboxes and thrusters.

Detected faults include:

- Broken teeth

- Pitting

- Misalignment

- Poor lubrication

Early detection prevents catastrophic gearbox failure.

5. Structural Looseness

Loose mounts and foundations amplify vibration.

Consequences:

- Cracked frames

- Misalignment

- Fatigue failure

Vibration trends expose these issues early.

How Vibration Analysis Works in Practice

A standard vibration monitoring process includes:

1. Data Collection

Sensors measure vibration in:

- Vertical

- Horizontal

- Axial directions

Measurements are taken at defined machine locations.

2. Frequency Analysis

Signals are converted into frequency spectra to identify fault sources based on known mechanical frequencies.

3. Trend Monitoring

Comparing data over time reveals deterioration trends.

This is far more valuable than one-time measurements.

4. Diagnosis & Recommendations

Experienced marine engineers interpret the data and recommend:

- Alignment

- Balancing

- Bearing replacement

- Overhaul scheduling

Why Vibration Analysis Is Better Than Breakdown Maintenance

Breakdown Maintenance

- Reactive

- Expensive

- Causes downtime

- Risks secondary damage

Predictive Maintenance (Vibration-Based)

- Planned

- Cost-effective

- Prevents failures

- Extends equipment life

Industry data shows predictive maintenance can:

- Reduce maintenance costs by up to 30%

- Reduce downtime by over 40%

- Extend equipment life significantly

Vibration Analysis vs Visual Inspection

| Aspect | Visual Inspection | Vibration Analysis |

|---|---|---|

| Internal faults | ❌ Not visible | ✅ Detected early |

| Real-time condition | ❌ Limited | ✅ Continuous |

| Failure prediction | ❌ No | ✅ Yes |

| Accuracy | Low | High |

Vibration analysis detects problems before visual signs appear.

When Should Marine Operators Use Vibration Analysis?

Vibration monitoring is recommended:

- After installation or overhaul

- After dry docking

- During commissioning

- When noise or temperature increases

- At regular operating intervals

- Before long voyages

Consistent monitoring delivers the best results.

How NASS Engineering Uses Vibration Analysis

At NASS Engineering, vibration analysis is integrated with:

- Laser shaft alignment

- Engine diagnostics

- Gearbox inspection

- Thruster and propulsion audits

- Dry dock support

- Condition-based maintenance programs

Our engineers combine field data with marine engineering experience to provide accurate diagnostics and practical solutions.

Real Benefits for Vessel Owners and Operators

Using vibration analysis leads to:

- Fewer breakdowns

- Lower repair costs

- Longer equipment life

- Better fuel efficiency

- Improved safety

- Higher operational availability

For offshore and defence vessels, this reliability is critical.

Conclusion — Vibration Analysis Is a Reliability Tool, Not Just a Test

Vibration analysis is not about finding faults — it is about preventing failures.

When used as part of a predictive maintenance strategy, it transforms how marine systems are maintained.

By understanding vibration behavior, marine operators gain control over maintenance schedules, costs, and vessel availability.

With deep expertise in marine diagnostics and propulsion systems, NASS Engineering Services Pvt. Ltd. delivers vibration analysis solutions that protect assets and extend service life.