Waterjet propulsion has become one of the most advanced and efficient propulsion methods in modern marine engineering. Known for its high maneuverability, shallow-water capability, and safety advantages, waterjets are widely used across offshore vessels, patrol craft, high-speed ferries, and specialized defence vessels.

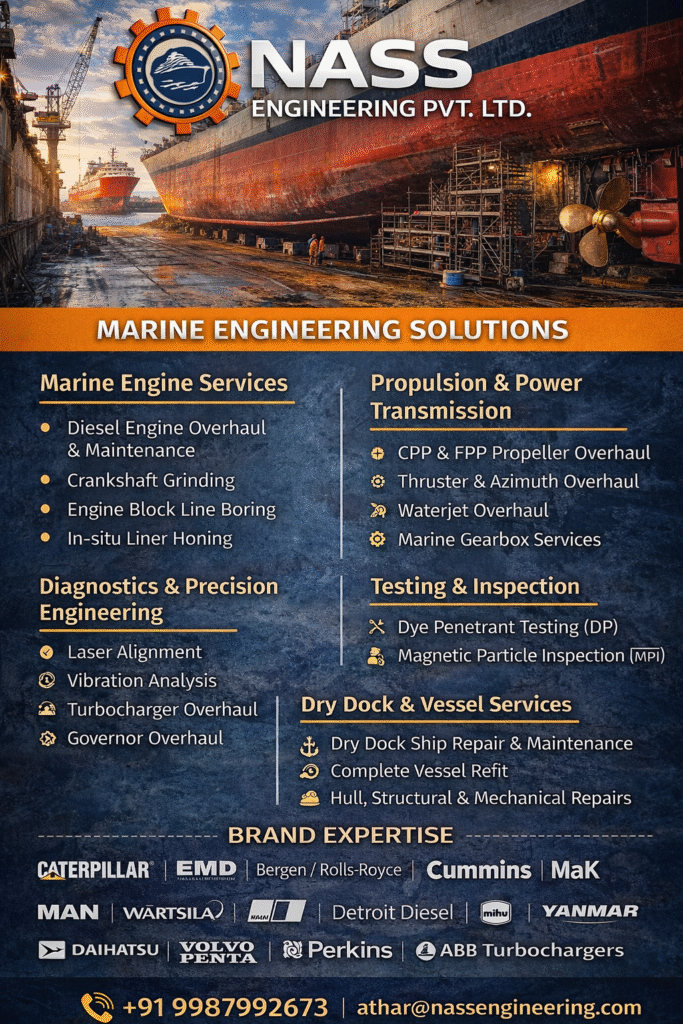

As marine engineering specialists, NASS Engineering Services Pvt. Ltd. brings extensive expertise in waterjet overhaul, inspection, component replacement, and performance optimization for vessels operating in challenging environments.

This blog explores how waterjet propulsion works, its advantages, maintenance requirements, and real-world applications across marine and offshore sectors.

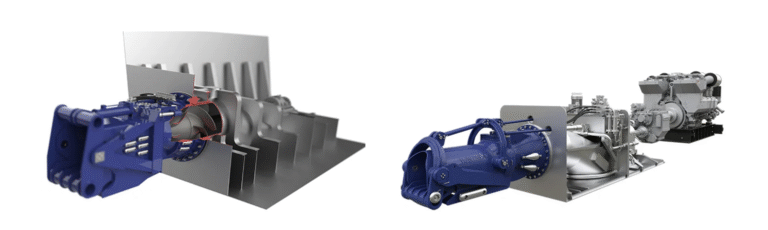

How Waterjet Propulsion Works

Unlike conventional propellers, waterjets do not use exposed blades. Instead, they generate thrust by drawing water into a pump inside the vessel and expelling it through a high-velocity nozzle.

The basic process involves:

1. Water Intake

Water enters through an intake duct positioned at the hull bottom.

2. Pump Impeller Rotation

A high-speed impeller accelerates the water.

3. Pressurized Jet Discharge

The pressurized water exits through a nozzle, producing thrust.

4. Steering & Reverse Control

Directional thrust allows the vessel to move forward, reverse, or turn without a rudder.

This closed-loop design makes waterjet propulsion safer and far more maneuverable than traditional propeller systems.

Advantages of Waterjet Propulsion

Waterjets offer multiple operational benefits, especially for high-speed and shallow-water vessels.

1. Exceptional Maneuverability

Waterjets can:

- Turn sharply at high speeds

- Stop almost instantly

- Move in any direction using vector thrust

This makes them ideal for patrol craft, rescue boats, and offshore support vessels.

2. Safer Operation

With no exposed propellers, waterjets significantly reduce risks of:

- Diver injury

- Propeller strikes

- Damage from floating debris

This is a major advantage for defence, rescue, and passenger vessels.

3. High-Speed Performance

Waterjets are most efficient at higher speeds and offer:

- Rapid acceleration

- Smooth handling

- Reduced cavitation

They are widely used in fast-response vessels that demand superior agility.

4. Shallow Water Capability

Because waterjets do not extend below the hull:

- The vessel can operate in shallow water

- There is lower risk of grounding

- Beach-landing operations become easier

This is crucial for coastal defence, offshore operations, and riverine transport.

5. Reduced Vibration & Noise

The enclosed pump system produces:

- Minimal vibration

- Lower acoustic signatures

- Improved onboard comfort

This is an important factor for naval and luxury vessels.

Common Waterjet Components That Require Maintenance

Although waterjets are robust, they operate under extreme hydrodynamic forces and require periodic servicing.

Key components include:

• Impeller & Pump Assembly

Wear from debris, sediment, or cavitation must be managed through regular inspection.

• Nozzle & Steering Unit

Hydraulic actuators and steering vanes must be checked for alignment and wear.

• Intake Duct

Clogging from debris or marine growth reduces efficiency and increases pump load.

• Shaft Seals & Bearings

Proper lubrication and seal integrity are essential to prevent water ingress.

• Control System

Electronic and hydraulic controls require calibration for smooth thrust management.

Routine checks help avoid thrust loss, vibration issues, and reduced maneuverability.

Waterjet Propulsion — Maintenance Best Practices

For optimal performance and long service life, marine research and engineering experience suggest the following maintenance practices:

1. Impeller Clearance Inspection

Impeller-to-wear-ring clearances directly affect jet pressure.

Incorrect clearance leads to:

- Thrust loss

- High fuel consumption

- Pump vibration

2. Intake Grate Cleaning

Regular removal of:

- Seaweed

- Plastics

- Sand

- Debris

ensures proper water flow and prevents pump overload.

3. Steering & Reverse Bucket Check

Hydraulic units must be inspected for:

- Smooth movement

- Seal leakage

- Corrosion on pivot points

Any stiffness or delay impacts vessel maneuverability.

4. Seal Replacement

Shaft seals face constant stress and must be replaced at recommended intervals to prevent catastrophic water ingress.

5. Wear Ring & Nozzle Inspection

Cavitation erosion is common in waterjets.

Regular monitoring prevents performance degradation and vibration problems.

6. Vibration & Alignment Checks

Though waterjets produce less vibration than propellers, misalignment in the pump shaft or drive line can create operational instability.

Applications of Waterjet Propulsion in Marine & Offshore Sectors

Waterjets are used in a variety of vessels due to their speed, safety, and maneuverability. Some of the most common applications include:

1. Defence & Patrol Craft

Coast Guard and Navy vessels use waterjets for:

- Fast interception

- High maneuverability

- Shallow-water missions

- Rapid directional changes

2. Offshore Crew Transfer Vessels (CTVs)

Waterjets provide:

- Smooth handling in rough seas

- Quick turns

- Efficient docking

Ideal for offshore wind, oil & gas support.

3. High-Speed Ferries

Passenger ferries benefit from:

- Quiet operation

- Low vibration

- High efficiency at speed

4. Rescue & Emergency Response Boats

Instant reverse and precise control allow safe navigation near people or obstacles.

5. Luxury Yachts

Their low noise and vibration make waterjets the preferred choice for comfort-oriented vessels.

Signs Your Waterjet System Needs Immediate Attention

Operators should schedule inspection if they notice:

- Reduced acceleration

- Excessive vibration

- Delayed steering response

- Overheating of hydraulic units

- Noise from pump or bearings

- Visible cavitation damage

- Loss of top speed

Timely maintenance prevents major failures and costly downtime.

How NASS Engineering Supports Waterjet Propulsion Systems

With specialized expertise across marine propulsion, NASS Engineering Services Pvt. Ltd. offers:

- Waterjet overhaul & reconditioning

- Impeller repair & replacement

- Steering bucket and nozzle servicing

- Shaft seal replacement

- Wear ring replacement

- Hydraulic system inspection

- Pump performance testing

- Dry dock support for waterjet removal & installation

Our engineers follow strict quality standards and ensure that every waterjet system operates at peak efficiency.

Conclusion — Why Waterjet Propulsion Matters

Waterjet propulsion represents a highly efficient, safe, and maneuverable solution for modern marine operations. With proper maintenance and expert servicing, waterjets deliver exceptional performance across defence, offshore, commercial, and high-speed vessels.

For reliable waterjet overhaul and propulsion system support, NASS Engineering provides proven expertise backed by years of marine engineering experience.